Small Things Equal Big Additive Opportunities for Holo

At a time when the 3D printing industry as a whole is “thinking big,” metal additive manufacturing company Holo is thinking small, but in a big way. The Newark, California company just announced the launch of PureForm MicroAM in copper, stainless steel, and other metals.

“PureForm's high resolution and high surface quality capabilities create design freedom for our customers, enabling them to design products that outperform traditionally made parts (i.e. the micro-inductors) or create unique products that couldn’t be made any other way, such as the intricate jewelry designed by Diamond Center Wales,” Arian Aghababaie, Holo’s co-founder, president, and chief strategy officer, says. “PureForm also provides manufacturing flexibility to our customers, making it economically viable for production runs from tens to tens of thousands of these complex parts without the traditional constraints of NRE or tooling costs.”

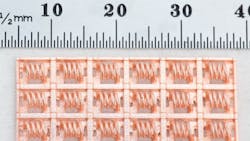

According to a company release, the new offering has already unlocked key capabilities within the electronics industry, producing fine-featured micro inductors coils, built with 400µm strands and in high-end custom jewelry.

“We’ve been blown away by the resolution and surface quality of the parts Holo can produce and are excited to explore the direct metal printing of jewelry with them,” said Simon Evans, senior manager, Diamond Center Wales, in a statement. “Leveraging the design freedom of additive and the fine features of PureForm will allow us to create truly unique, custom pieces for our clients that couldn’t be made using other manufacturing processes.”

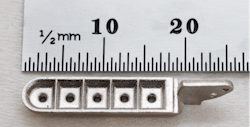

Other potential applications include stainless steel biopsy scoops used in medical applications with sharp point features, down to 20µm, and dental abutments with printed functional threads that hold a 200µm pitch.

According to Aghababaie, PureForm can produce parts in any material that can be powdered and sintered, resulting in broad impact of the technology. “In our launch materials, our high purity, high conductivity copper opens up capabilities for electrical and electronics applications that haven’t been possible before in AM,” he says. “While in stainless steel and other metal products that have been traditionally made using metal injection molding (MIM) or Swiss CNC, PureForm eliminates the design constraints and costs of tooling, which impacts applications from consumer electronics to medical devices.”

The ability to produce fine-featured geometries at production scale creates a bright future for PureForm, explains Aghababaie. “We’re continuously advancing our platform with a focus on resolution, speed, and materials offering,” he says. “Our next-generation printer will increase throughput to 3,000cm^3, without sacrificing feature resolution and we’re expanding our materials offering, with cobalt chrome and aluminum currently in development.”

Based in Silicon Valley, Holo leverages additive manufacturing to create product performance unachievable any other way. Holo’s pilot production facility, located in Newark, California, is ramping up to produce tens of thousands of parts per month. As a spinout of Autodesk in 2017, the founding team brought their additive manufacturing expertise to develop proprietary 3D printing hardware and materials from the ground up. Now, the Holo team leads in expertise in additive manufacturing, material science, mechanical engineering, and thermodynamics.

About the Author

Peter Fretty

Managing Editor

As a highly experienced journalist, Peter Fretty regularly covers advances in manufacturing, information technology, and software. He has written thousands of feature articles, cover stories, and white papers for an assortment of trade journals, business publications, and consumer magazines.