Private Mobile Networks: A Wireless Connectivity Option for Smart Manufacturing

Just in the last few years, a multitude of new technologies and methodologies have emerged that are forcing manufacturing organizations to reevaluate their networking architectures. Whether it is 5G, the Industrial Internet of Things (IIoT), low-power wireless protocols, open-source hardware, or some combination of these new tools, there is little doubt that big changes are coming to connectivity on and around the factory floor. Some of these technologies are coming sooner than others, however, and it’s up to manufacturers to sort near-term practicality from marketing vaporware.

One recent development that has immediate potential for manufacturers is the decision earlier this year by the FCC to make the Citizens’ Broadband Radio Service (CBRS) spectrum band available for use by businesses. The net result is that manufacturers now have a new option for predictable mobility that can serve a variety of needs on mission-critical infrastructure from the factory floor, process automation using automated guided vehicles (AGVs), inventory management via rugged tablets that can also be vehicle-mounted, voice communications with push-to-talk handsets, and much more. This new option is called a private mobile network and it is poised to change how manufacturers view wireless networks in their environments.

First, let’s provide some background on what we mean by a private mobile network in the context of manufacturing. We all know that manufacturers heavily rely on wireless connectivity both indoors and outdoors, two different environments that present separate challenges for different types of wireless technologies. For the last two decades, “wireless” in a manufacturing setting meant two things; Wi-Fi or a public cellular network.

The advent of private mobile networks is something new. They are very similar to the public cellular network that most of us use every day with our smartphones and tablets. They are built on technologies like LTE and soon 5G as the wireless protocols for connectivity, but the networks themselves are not owned and operated by wireless service providers like Verizon, AT&T, and others. A private mobile network is an LTE or 5G network that is owned and operated by a single organization and geographically bound by that company’s property (like a smart factory). In the U.S. these networks use the CBRS spectrum band between 3.55 and 3.7Ghz and can be used by manufacturers to give them their very own LTE or 5G network, but managed as easily as the Wi-Fi network.

So why add a new wireless option? First, a private mobile network based on the CBRS spectrum operates within a dedicated and interference-free spectrum by FCC regulations in the United States. Not only does this significantly reduce the ongoing operational expenses and support costs, but it also makes a private mobile network ideal for applications that need to be up and running at all times. IIoT devices and systems need ultra-reliable connectivity in order to perform their core functions and, from a wireless perspective, private mobile networks are the only option capable of delivering on that requirement.

In addition to reliability, CBRS-based networks provide the type of latency that manufacturers need for both current systems and future applications. Even if based on LTE, a private mobile network can provide specific performance guarantees at an established Quality of Service (QoS). Today’s networks deliver sub-20 millisecond latency. That latency will be even further reduced for private mobile networks based on 5G. This is a critical requirement for any type of factory automation task and for many IIoT applications.

Another benefit of this new spectrum-based “traffic lane” is that it ensures the manufacturing data traffic is kept local and separate from networks that may be used by guests or other personnel that do not need access to secure data. That built-in security can be a critical element for business and safety reasons.

CBRS-based private mobile networks are also ideal for connectivity across outdoor settings such as transportation yards, outdoor warehouse locations, or manufacturing site parking lots. With the ability to cover one million square feet of outdoor space with a single outdoor wireless access point, a private mobile network significantly reduces the amount of outdoor cabling required to support a wireless network infrastructure—reducing a good chunk of your capital expense.

Private mobile networks are an ideal extension of another new networking architecture that is quickly establishing itself in the manufacturing sector—edge computing. As demands for low latency and computing intelligence increase, most network architects are looking for the means to place at least some of this functionality physically closer to applications themselves, thus making the “edge” of the network closer to “action” so to speak. Analytics, information applications, business processes, and other functions will likely still reside in the cloud or in an onsite data center, but private mobile networks can extend operational technologies and thus the network edge to the factory floor for system automation, delivering predictable communications for guided vehicles, and guaranteeing reliable communications for floor staff.

I should add that there are likely those manufacturers that do NOT yet need a private mobile network. If you are not pushing the limits of your current wireless network or if you are not looking at business process automation or the IIoT, it’s possible you do not have a need for this technology yet.

However, if you do feel a private mobile network could help, let’s discuss the considerations required before you decide how you can implement this technology. There will likely be many different ways of implementing them, depending on the specific needs of your IT department. Some groups will want to have this supplied to them and managed by a third party, like a service provider or channel partner. Others may wish to simply purchase an end-to-end system and install and manage it themselves.

One of the biggest issues is figuring out the total number of indoor and outdoor CBRS LTE access points (AP) you might need at your facility given size, geo-location, density, and performance requirements. Let’s look at one scenario for an indoor factory and what would be required for establishing total network coverage, but also then designing that network to provide maximum capacity as well.

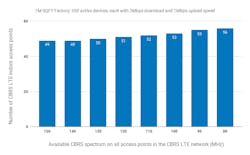

First, if you are designing for coverage, CBRS spectrum availability does not impact the number of APs required in your network. In the standard mode of operation, since all traffic flows in the download and upload direction to an LTE radio is scheduled by the infrastructure, even a single channel of 10MHz across all APs will work. If you are designing for network capacity, as you move from the maximum possible 150MHz of CBRS spectrum availability across your entire network to 80MHz—which happens to be the worst-case scenario for any environment in the United States—you are looking at about only a 10 to 15% increase in the total AP count in your network.

If we consider an indoor facility size about one million square feet, there is a reasonable chance most facilities this size will have around 2,500 devices (give or take a few dozen) active simultaneously. In this scenario, we would require around 43 APs to ensure highly-reliable coverage of the entire facility. If you’re designing for capacity, we’ve included a chart below that details what kind of infrastructure will be needed, assuming a download capacity of 3 Mbps and an uploaded capacity of 1 Mbps.

As you can see, the design scenarios for manufacturers to implement private mobile networks are already well-defined and available. If you find this type of tool useful, Celona’s network planner is available at https://planner.celona.io. There are others that would give you the ability to compare and contrast multiple solutions from different vendors, as any reasonable purchaser would need.

The bottom line is that private mobile networks offer a robust solution for multiple near-term manufacturing needs. In an era in which we are assailed with far-off applications and nice-to-have functionality, private mobile networks deliver real performance with practical value today. If you’re in need of mobile performance with significant ROI, you owe it to yourself and your business to take a closer look at private mobile networks.

For more information, please visit celona.io

About the Author

Dr. Mehmet Yavuz

CTO and Co-Founder, Celona

Mehmet is the co-founder and CTO at Celona where he provides the technology vision for the networking platform for enterprise 5G. Previously he was the CTO of Ruckus Wireless and vice president of Engineering at Qualcomm Corporate R&D. While at Qualcomm, Mehmet led the LTE small cells group and the 1000x initiative in Qualcomm Research, including areas such as Self Organizing Networks, Neutral Host services, LTE in Unlicensed or Shared Bands, and the work on 5G Internet of Things (IoT) networks for industrial IoT applications. Mehmet has more than 160 issued patents with USPTO and received Qualcomm IP Excellence Award in 2013. He holds M.S. and Ph.D. degrees in Electrical Engineering from the University of Michigan, Ann Arbor.