As today’s manufacturing environments increasingly depend on digital capabilities, enabling seamless – and often wireless – connectivity plays an instrumental role. And, the growing use artificial intelligence, autonomous vehicles and robots as well as expansive growth of IoT networks only intensifies the need for stronger and more dependable connectivity.

“5G, Wi-Fi and Bluetooth are all combining to provide the critical connectivity infrastructure driving this transformation. However, perhaps the biggest missed opportunity right now is simply the pace of adoption. Industrial and commercial applications have historically moved slower than consumer tech,” says Bluetooth SIG’s Senior Director Market Development Chuck Sabin. “Overcoming the inertia of legacy systems is tough. However, we continue to see momentum and an increase in Bluetooth industrial networks and things like connected lighting platforms throughout warehouses. Industry R&D and deployment is often what is needed to really launch emerging technology into the mainstream.”

Having recently published the 2020 Market Update, Sabin tells IndustryWeek there are a few notable use cases where the Bluetooth technology is demonstrating its prominence in smart manufacturing environments. “Bluetooth sensor networks are deployed at scale across the factory floor enabling real-time condition monitoring of machines, motors, and other critical systems – providing vital information to schedule maintenance, reduce downtime and prolong the life of expensive machines,” he says. “Manufacturers are also utilizing Bluetooth for asset tracking and management solutions allowing manufacturers to better monitor location, availability, and inventory of equipment and output across the supply chain.”

According to Sabin, the potential exists for Bluetooth to empower a growing array of additional applications. “Direction finding with increased levels of precision can be used in monitoring worker safety and security. Connected devices like phones, tables or enterprise wearables can alert a worker as they approach a harsh environment or alert a central monitoring facility if an employee has been exposed to a dangerous substance,” he says.

Bluetooth’s growing role in workplace safety and security is echoed in this year’s survey results. Specifically, 60% of respondents are currently testing or deploying smart workplace management solutions. Whether that’s via access control, geofencing, or personnel tracking, Bluetooth tech helps ensure the safety and security of facility occupants, monitoring staff positions, and keeping employees away from hazardous areas.

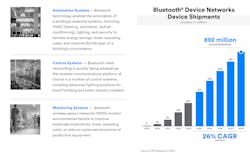

Additionally, Bluetooth expects a 4.6x growth in Bluetooth smart building location service devices by 2024. Bluetooth tech is becoming the default solution for enabling in-building wayfinding, asset management, and space utilization. As Bluetooth continues to power location services in smart buildings, more opportunity is becoming available to create more operational efficiencies and improving the occupant experience.

“Long-range Bluetooth industrial IoT edge routers can also provide a range of benefits including improved reliability for data collection over long distances, remote access and control, one-to-many connectivity and edge computing all within an easy-to-use centralized management platform,” says Sabin. “Bluetooth technology is an ideal solution for edge computing because it is widely available, requires minimal power consumption, and is extremely low cost.”

Flexibility is the most significant benefit to Bluetooth, especially as manufacturers begin experimenting with its potential, explains Sabin. “A manufacturer may start by using Bluetooth beacons for asset tracking and then realize the same network can be expanded to include access control, condition monitoring or even centralized automation of a factory’s essential systems— including lighting, heating, ventilation and air conditioning (HVAC) and security,” he says.

About the Author

Peter Fretty

Managing Editor

As a highly experienced journalist, Peter Fretty regularly covers advances in manufacturing, information technology, and software. He has written thousands of feature articles, cover stories, and white papers for an assortment of trade journals, business publications, and consumer magazines.