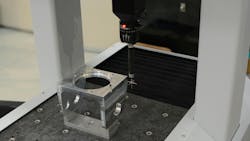

RUN Coordinate Measuring Machines (CMM) for Shopfloor Inspection

RUN is a line of coordinate measuring machines (CMM) designed for use directly in production environments. The systems provide measurement results on the shopfloor to support inspection, feedback, and control during manufacturing processes.

RUN systems are designed to integrate into production workflows and support simplified measurement processes. Linear motors are used to enable operation without air supply or lubrication, supporting long-term operation in production environments.

The Easy Runner interface allows operators to load and run inspection programs with a single touch. A moving table design supports part handling, and an optional clamping kit is available to assist with ergonomic setup. The moving table structure keeps both the portal and measuring head outside the moving range, supporting safer setup procedures and faster part loading. Operators can switch between parts by scanning a barcode to load the appropriate inspection program, with measurement and reporting carried out automatically.

RUN systems include design elements intended to support accuracy and repeatability in shopfloor conditions. These include an automatic stylus cleaning unit and an active anti-vibration granite base with pneumatic dampers.

The systems are intended for end-of-line inspection and in-process verification. Measurement data is available immediately to support the detection of deviations, scrap reduction, and shorter setup times. Integrated CAD import and GD&T analysis provide insight into part geometry and support verification against specifications.

Features:

- Coordinate measuring machines designed for production environments

- Linear motor drive system without air supply or lubrication

- Easy Runner operator interface for program execution

- Moving table design for part handling

- Optional clamping kit for ergonomic setup

- Barcode-based program selection

- Automatic stylus cleaning unit

- Active anti-vibration granite base with pneumatic dampers

- CAD import capability

- GD&T analysis functionality

- Support for in-process verification and end-of-line inspection

Ready

Torino, Italy

+39 011 96 35 511

[email protected]

readymetrology.com