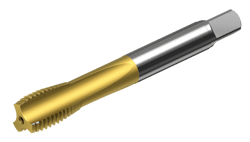

CoroTap 100 -PM Improves Chip Control in Steel Threading

CoroTap 100 with -PM geometry is a family of optimized straight flute cut taps for ISO P materials. The taps have a high-performance chip-breaking design to improve chip control and thread quality, reducing production interruptions and eliminating manual chip removal. The result is a more stable machining process with consistent output and reduced operator involvement.

The -PM geometry integrates a chip breaker chamfer on two flutes to enable efficient chip separation while maintaining thread accuracy and surface finish. Internal coolant delivery ensures clean chip evacuation and a high-quality finish in blind holes, while external coolant via collets or nozzles is recommended for through-hole applications.

The tap range includes multiple geometries tailored for ISO P, K, N, and H materials. Options include straight flute taps, spiral point taps, spiral flute taps, and forming taps to address a wide variety of threading needs.

Features:

- Optimized straight flute cut taps for ISO P materials

- -PM geometry with two-flute chip breaker chamfer

- Improved chip control and thread quality

- Internal coolant delivery for blind holes

- External coolant recommended for through holes

- Reduces manual chip removal and operator intervention

- Provides stable machining with continuous output

- Available for ISO P, K, N, and H materials

- Offered in straight flute, spiral point, spiral flute, and forming tap versions

Sandvik Coromant

Mebane, NC

(800) 726-3845

[email protected]

sandvik.coromant.com