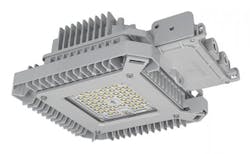

Appleton Baymaster LED Luminaire

Appleton Baymaster LED High Bay luminaire features a quick-mount pendant system that makes it faster, safer, and more cost-effective than ever to install high bay LEDs in harsh industrial and hazardous locations.

Emerson designed the Appleton Baymaster LED with the understanding that replacing traditional HID or fluorescent high bays with energy-efficient LED technology can be costly and difficult. Because most high bay luminaires are heavy and in hard-to-reach locations, two or more people are required to perform installations, leading to increased labor costs.

Emerson's Appleton Baymaster LED answers the need for improved lighting quality with unprecedented innovation and unique-to-industry design. Secondary optics help shape the Baymaster LED's light to meet precise application needs while eliminating glare and dark spots. With a choice of aisle, narrow, medium or wide beam spreads, it is now possible to offer optimal light distribution in challenging areas such as aisle ways and walkways. Its six-lumen output levels (9500K to 38000K) and 5000K cool white or 3000K CCT warm white color options provide greater mounting height versatility and superior light quality wherever it is installed, making it an ideal replacement for HID high bay luminaires from 175 to 1,500 W.

Emerson's Appleton Baymaster LED delivers peace of mind even in the harshest industrial and hazardous locations. Since reliability is the key to lower maintenance costs, Emerson gave the luminaire unprecedented resistance to corrosion, vibration, surges, thermal shock, and moisture. Mounting hoods and bodies are forged from copper-free aluminum protected by a baked epoxy-clad finish, electrostatically applied for complete uniform protection. The result is an industrial LED rated for 84,000 hours with luminaire life that can exceed 200,000 hours depending on ambient temperature. Plus, unlike fluorescent alternatives, LED luminaires are instant-on, impervious to cold-start up, and do not fail prematurely due to frequent on-off cycling.

- NEC/CEC Certifications and Compliances: Class I, Division 2, Group A, B, C, D; Class I, Zone 2, Group IIC; Class II, Division 1&2, Group E, F, G; Class III; Zone 20 and 21 Group IIIC; Zone 22 Group IIIB; Marine Outside Type (Salt Water) for USA Only; Wet Locations; Type 3R, 4 and 4X; ATEX/IECEx: Zone 2 and 22

- Standard Materials: Copperfree (4/10 of 1% max.) aluminum housing, lens door, quick-mount hood, and body. Silicone rubber gaskets and stainless steel exterior hardware, guard, and safety cable. Aluminum close up plugs

- Standard Finishes: Housing, lens cover, quick-mount body, and hood have electrostatically applied baked gray epoxy powder coat finish

- Options: Safety cable, guard, 10kV surge protection, Y mount cable assembly, and drain assembly are available. See catalog pages for details

- ATEX/IECEx Certifications and Compliances: Zone 2 - 21 and 22; II 2 D and II 3 GD; IP66/67 - IK10