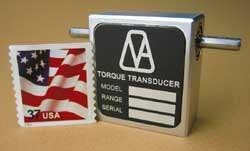

Series MLY Miniatrue Torque Transducers

Series MLY torque transducers fulfill the need for small size, low inertia, robust, and economical instruments for measuring torque in ranges from ±10 to ±1000 mNm. (1 mNm = 0.1416 oz in). Just two different case sizes and three shaft sizes cover this full range of torques. MLY transducers offer those involved in the world of small machinery a size compatible means to monitor and control the torques involved in the operation of their motors, mechanisms, instruments and tools. Non contact torque sensing is intrinsic in MLY transducers; nothing except the supporting bearings is attached to the rotating shaft. Operation is based on polarized band magnetoelastic technology, wherein a central “active” portion of the shaft, sized for the user specified measurement range, generates a magnetic field proportional to the transmitted torque. This is converted into an electrical signal by a pair of Hall effect field sensors. Combined error due to non-linearity and hysteresis is within ±1% of the full scale range. Connections to external power source and signal conditioning, display, or data acquisition circuits, are made through user selected pigtail leads, attached, or detachable cable. All internal electrical/electronic parts are encapsulated. MLY transducers accommodate both rigid and shaft mounted arrangements. Torque may be coupled to the transducer shaft via gears, pulleys, linkages, etc., as well as through conventional inline couplings. Custom, user specified mechanical details and accessories are available. Signal conditioning electronics, both internal and external, are also available.