SAFETYCROSS® MAGNETIC WHITEBOARDS ENGAGE EMPLOYEES IN MAKING SAFETY AWARENESS A DAILY JOB

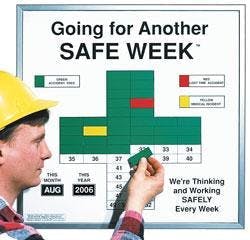

Safety is a top priority for any manager and supervisor in a factory, plant, stockroom or worksite. But, unfortunately, workplace safety awareness is not always up front in the minds of workers. With that in mind, Magnatag Visible Systems has introduced its solid-green SafetyCross motivational line of magnetic printed white board kits.Safety is a top priority for any manager and supervisor in a factory, plant, stockroom or worksite. But, unfortunately, workplace safety awareness is not always up front in the minds of workers. With that in mind, Magnatag Visible Systems has introduced its solid-green SafetyCross motivational line of magnetic printed white board kits.Prominently displayed in the workplace, each employee team posts its own SafetyCross board with magnets, visually engaging them in safety awareness all day, showing each safe day, week or month with a green magnet.. A red or yellow “accident” magnet stands out among a collection of safe, green magnets on the SafetyCross but is an incentive to improve. It’s a win-win situation for everyone concerned.“There is nothing more important than the safety of workers in any facility, but employees and managers alike can fall into bad habits – taking short cuts or not communicating about safety,’’ said Wally Krapf, founder and President of Magnatag Visible Systems. “Some customers will post several years of SafetyCrosses. So a proud accident-free or embarrassing unsafe accident year lives on in people’s minds. The visible message of Magnatag’s magnetic SafetyCross is very powerful.”Customers are already using SafetyCross systems as a critical tool in their workplaces:“They are an important part of our Safety Awareness Program,” said a Safety Manager for an auto parts manufacturer, a 600-employee facility in Holland, MI. “Nobody wants to have someone from another department come by and see a red or yellow mark (denoting an accident) in their area.”“Bringing the boards and the emphasis on safety down to the department level has made our program twice as effective. Our departments take a good bit of pride in logging a few green accident-free months,” said a Manager of Industrial Safety and Hygiene for a floor covering manufacturer, of Lyerly, SC, a 900-employee facility.“When an accident pops up people are very aware of it, very concerned about the cause and that is exactly what I want it to do,’’ said a Safety Manager, for an electronics manufacturer in Lexington, NC.“The boards really help get the message out; we use 3, one each in the entrance, cafeteria and the shop floor,’’ said a Safety and Hygiene Coordinator for a 200-employee auto parts manufacturer in Lugoff, SC. “We’ve had our best results when we post the information prominently. The boards really help get the message out.”SafetyCross boards let workers and supervisors track a full year of safety one day, week or month at a time. They come in two sizes: 2’ by 2’ boards you can read from 10 feet; and 3’ by 3’ boards readable at 50 feet. Kits include die-cut magnets in 3 colors to mark accidents and accident-free periods. The boards are priced from $239 with quantity pricing available for multiple boards purchased in the same transaction.