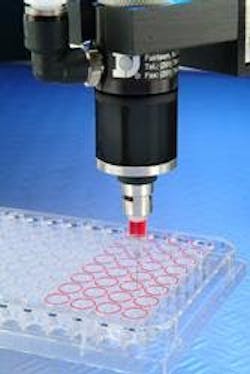

DV509-UV-LF High Duty Diaphragm Valve for UV Resins

UV resins are a diversified range of products. They perform three principal functions: Bonding, Coating, and Sealing. For many UV resins, polymerization can only be achieved by exposure to UV light. A significant advantage of using these products is that they provide time for assembling components and for making adjustments. Polymerization occurs rapidly after exposure to an intensified UV source. Since natural sunlight radiates UV rays, the resin has to be protected. Some UV resins are also anaerobic and are sensitive to metal contact, not sufficient to polymerize but enough to gel. The Model DV509-UV-LF is a diaphragm action valve that has been designed for UV resins. The wetted chamber is compatible for low to medium viscosity UV materials. The valve is high cycling, rated at 200 cycles a minute and its lightweight compact design makes it especially suitable for automated systems. A Diaphragm seal is attached to a solenoid that opens upon receiving an air signal from an I&J Fisnar Inc. valve controller. The diaphragm flexes to allow fluid to exit for the duration that the seal is opened. A return spring snaps the diaphragm shut after the air signal is removed. The DV509-UV-LF is easy to maintain and is a cost effective solution to dispensing UV resins and adhesives.• Ratio Range: 1:1 - 25:1 • Ratio Accuracy: +/-1% • Viscosity Range: 1cps to 2,000,000cps(viscous materials may require heating or pumping) • Shot Size range: 1/10cc-continous.