Polyurethane Hose Material Meets FDA Standards

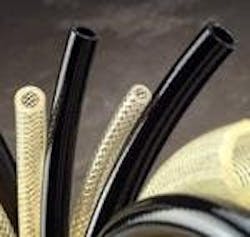

Urebrade® polyurethane hose, manufactured by NewAge® Industries, is now made from non-toxic ingredients that conform to the Food and Drug Administration’s standard 177.2600 (rubber articles intended for repeated use). A durable product that handles repetitive flexing and abrasion, Urebrade is now well suited for wet and fatty food applications and beverage processing. It remains practical for industrial uses such as air lines, pneumatic control systems and robotics, low-pressure hydraulics, chemical transfer, vacuum equipment, granular material lines, oil and fuel supply*, and petroleum-based product* transfer. Urebrade is produced from a compound that, in addition to conforming to FDA standards, is listed by the National Sanitation Foundation’s Standard NSF 61 for drinking water system components. It’s manufactured from ether-based polyurethane reinforced with an open mesh polyester braid to allow much greater pressure capabilities over unreinforced tubing. The greatest advantage of Urebrade is its long service life versus other hose materials containing plasticizers, which are additives used to make plastics more pliable. Urebrade is naturally flexible and does not require plasticizers. The hose experiences no flexibility loss, hardening, or cracking like other materials can as their plasticizer migrates out. This adds to Urebrade’s longevity and can reduce hose replacement costs. Urebrade’s resistance to flow contamination, moisture, fungi, weathering, tearing, impact, and radiation exposure, along with its appropriate use at temperatures ranging from –90°F (-67°C) to 175°F (79°C), make it a preferred choice. Urebrade is manufactured in a transparent formulation in sizes from 1/4” through 2” I.D. For industrial applications opaque black color, available from 1/4” to 3/4” I.D. and offered at a reduced price, may be used. Both versions are well stocked for immediate delivery. Custom services such as cut-to-length pieces, heat-formed shapes, other sizes and colors, thermal bonding, and hose assemblies are available. * Open mesh polyester braiding incorporated within the walls of flexible, ether-based polyurethane * Transparent ether-based polyurethane is made from non-toxic ingredients conforming to FDA standards and is listed by the National Sanitation Foundation (NSF 61) for use with potable water * Offers much greater pressure capability than unreinforced polyurethane tubing * Resistant to weathering^, tearing, impact, abrasion, and radiation exposure, oils, greases, & fuels^^ * Wide range of temperature resistance; -90°F to 175°F * Contains no plasticizer which can migrate and cause flow contamination or tube hardening * Naturallly transparent for visual contact with the flow