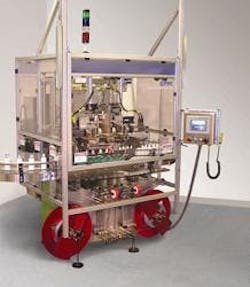

90 Series Shrinksealer

. PDC International Corporation, a leading developer and manufacturer of tamper-evident packaging and labeling machinery, has introduced the 90 Series Shrinksealer, an advanced new in-line applicator that combines high speeds (up to 500 containers per minute) with true “zero shutdown” performance. Systems will run as slowly as 200 cpm to synchronize with slow-downs on processing systems. 90 Series Shrinksealers apply bands .375 inches to 3.0 inches (10 to 75 mm) diameter and .625 inches to 8 inches high, making them suitable for a broad range of products. Monolayer and multilayer PVC, PETG, PLA, and OPS films, in gauges as thin as 40 micron, (1.5 mil) are compatible, depending on throughput rate and cap configuration. PDC ‘s Reel Changeover feature makes this critical function automatic, eliminating downtime for operator action, and allowing a second reel of material to be loaded while operation progresses at normal speed. A detection feature senses when the initial reel is spent and automatically engages the new reel. Standard features of the 90 Series include stainless steel frame and covers, NEMA 4 enclosures, Allen-Bradley PLC with touch-screen interface, and static eliminator. Systems are supplied with complete tooling. There are sensors for low material and film feed irregularity, and available sensors for imprint and bar code verification. As with all PDC shrink sealing systems, conveyors and heat tunnels can be provided as part of the package. The 90 Series interfaces easily with PDC’s Smooth Diversion Inspection / Ejection System, which confirms the location of bands and gently diverts any imperfect packages without disrupting operation. PDC 90 Series Shrinksealers are UL and CE approved. As with all PDC systems, the use of readily available components minimizes operation costs and difficulties throughout the system’s long service life.