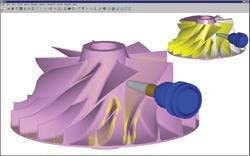

Turbomachinery Applications

NCCS, the developer of NCL multi-axis machining software for the aerospace, automotive and turbomachinery industry, introduces new strategies for multi-axis machining within NCL designed to create complex turbine components requiring 5-axis machining. Turbomachinery Application Library NCCS has enhanced its Turbomachinery Application Library (TAL) to aid the user in the manufacture of complex turbine components. • The TAL addresses the manufacturing of complex rotary parts such as impellers, blisks, airfoils, and inducers. • New toolpath strategies have been added for efficient machining of hard materials such as stainless steel and titanium. • The new strategies are designed to decrease machine type, provide longer tool life, and create optimum finishes. This application helps to speed up the programming of such complicated parts thereby, allowing the user to be more productive. According to David Schultz, NCCS’ Manager of CAD/CAM Applications, “At NCCS, we offer a high-end technology that enables our customers to achieve the highest quality in the shortest time. The Turbomachinery Application Library helps to address the unique requirements of these specific applications”.