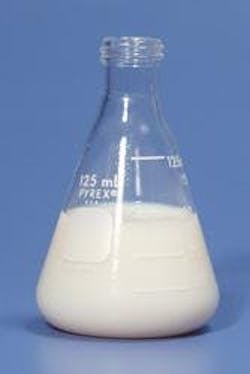

TRIM® E906, A PREMIUM LONG LIFE, LOW FOAM EMULSION

Master Chemical Corporation announcesthe introduction of a new premium low foaming emulsion, TRIM® E906. Thislow foaming formula delivers consistent machining and grinding performanceon a wide range of materials and applications. "E906 provides the newestavailable technology into our proven emulsion-based cutting platform," statedGlobal Marketing Manager, David A. Barned. The stable and predictableperformance of E906 makes it a first choice for manufacturers doing work forindustries as diverse as aerospace, automotive, energy, and specialty jobshops. Using E906 on the newest CNC machine tools that utilize high-pressure, high-volume, through-the-tool coolant systems will help plantsmaximize their productivity.E906 provides a much longer operational life without the need for costlyadditives than competitive fluids. E906 is effective in a wide range ofoperations from production surface and centerless grinding to heavy-dutybroaching, gear hobbing, surface, pocket, and thread milling. "In high-speedturning and milling, E906 has the right balance of cooling and lubrication toprovide great tool life and surface finishes because it has a tight emulsionwhich reduces carryoff and gets the fluid to the point of cut," stated Mr.Barned. E906 also protects machine tool surfaces while preventing stickyways, chucks, tool holders, and fixtures. E906 does not contain or testpositive for phenol, is easily removed with water, working solution, or TRIM®CLEAN aqueous cleaners. E906 is easy to recycle or dispose of withconventional techniques and equipment. * Longer operational life than competitive fluids * Highly effective, extreme pressure additives control built-up edge * E906 is effective in a wide range of operations from production surface and centerless grinding to heavy-duty broaching, gear hobbing, surface, pocket, and thread milling * Low odor for pleasant operating environment * Tight emulsion reduces carryoff and gets the fluid to the point of cut * In high-speed turning and milling, E906 has the right balance of cooling and lubrication to provide great tool life and surface finishes * Low foam and low mist make it a first choice for high-pressure, high-volume coolant systems * Protects the machine tool surfaces while also preventing sticky ways, chucks, tool holders, and fixtures * Coolant is easily removed with water, working solution, or TRIM® CLEAN aqueous cleaners * Easy recycling or disposal with conventional techniques and equipment * Does not contain or test positive for phenol * Will run effectively for long periods without the need for costly additives