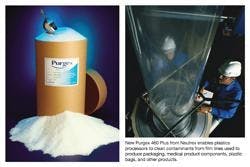

Purgex® 460 Plus to Purge Blown Film Lines

Neutrex, Inc., Houston, Texas announces the introduction of its new Purgex 460 Plus commercial purging compound (CPC) for cleaning film lines. According to the company, the new CPC is a strong blend that is effective for purging heavily contaminated lines, particularly those infrequently purged. It can also be used to purge sheet molding lines. Neutrex reports that using Purgex 460 Plus will result in shorter cleaning cycles, lower purging material costs, and greater reliability in controlling the release of contaminants during production runs. Supplied ready-to-use, Purgex 460 Plus is engineered for commodity resins, specifically polyolefins. It is designed for color and/or material changes and the removal of residual contamination, cleaning the extruder, screen pack housing, and die/manifold, removing all types of color bodies, carbonized material and degraded resins. Neutrex states that Purgex 460 is very effective in purging the new series of biodegradable and compostable polyethylene resins that are growing in popularity and availability. New Purgex 460 Plus is a blend of low-linear polyethylene carrier and FDA-approved active ingredients that are non-toxic, non-abrasive and safe. Supplied in pellets without fines, the new CPC has an operating temperature range of 250°F to 450°F (120° to 232°C) and is easy to remove, according to Neutrex.