Custom-Engineered Transfer Chutes Improve Conveyor Loading, Reduce Blockages

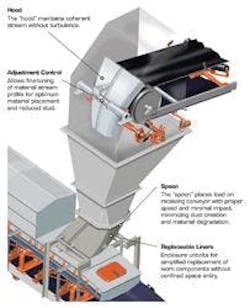

One of the world’s most experienced suppliers of bulk materials handling equipment has introduced custom-engineered transfer chutes, helping to deliver material control from the time it leaves the conveyor discharge pulley until it reaches the receiving belt. By managing the material speed and direction, MARTIN® Inertial FlowTM Transfer Chutes can minimize impact and wear on liners and belts, while containing the dust and spillage that are often generated at transfer points. The engineered flow chutes employ special geometries that capture and concentrate the material stream as it travels through the chute. Every design is tailored to suit the specific material characteristics and conveyor systems of the individual customer, rather than using stock products and attempting to make them work. Inertial Flow Transfer Chutes from Martin Engineering provide the dual benefits of minimizing aeration and preventing buildup within the chute, particularly important when dealing with combustible materials. “Transfer points should never be a production bottleneck,” commented Martin Product Development Engineer Justin Malohn. “By testing the customer’s specific bulk material and applying those properties as the initial step in chute design, we can develop a transfer that meets capacity while minimizing the potential for build-up and chute plugging,” he said. MARTIN Inertial Flow Transfer Chutes also incorporate replaceable liners, allowing operators to unbolt the enclosure for simplified replacement of worn components without confined space entry.