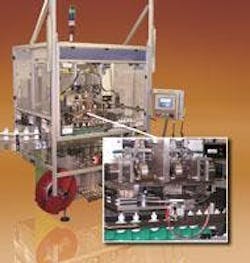

High-Performance Shrink Sealer

PDC International Corporation, a world leader in high-volume, tamper-evident packaging and shrink labeling, has introduced the 90-2 Shrink Sealer. The 90-2 is based on PDC's highly successful 90 Series Shrink Sealer, and was engineered for the largest, most demanding projects. Dual-head capability means the 90-2 will seal over 400 containers per minute, with true 24/7, downtime-free performance. Variable in speed, the system can also run as slowly as 100 cpm per head to synchronize with production. 90-2 Shrink Sealers apply single and multi-layer PVC, PETG, PLA, and OPS bands, in gauges as thin as 40 micron, (1.5 mil). Compatible diameter ranges are .375 inches to 3.0 inches (10 to 75 mm); height ranges are .625 inches to 8 inches. The PDC 90-2 Shrink Sealer was designed to be a precise, practical solution for the widest range of containers, caps configurations and throughput requirements. It is ideally suited for the health and beauty, OTC pharma, and food and beverage sectors, where uptime levels are most critical. PDC‘s Reel Changeover feature plays the central role in the "true 24/7" promise of the 90-2 Shrink Sealer. By allowing a second reel of film to be staged while operation continues at normal speed, the traditional downtime for operator intervention is eliminated. When the current reel is spent, an end-of-reel sensor automatically shuttles the second head into position and engages the new reel. Standard features of the 90-2 include a stainless steel frame, NEMA 4 enclosures, Allen-Bradley touch-screen and PLC, static eliminator, and a robust blade assembly that does not use unreliable spinning knives. There are sensors for low material and film feed, and available sensors for imprint and bar code verification. Both vertical and horizontal perforators may be added.

- dual-head capability

- will seal over 400 containers per minute

- variable in speed