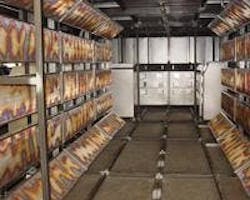

Infrared Ramp Ovens

Catalytic Industrial Systems, a manufacturer of high-efficiency oven systems, is introducing its high-efficiency ramp oven technology. Catalytic infrared ramp ovens - sometimes called "gel" or "booster" ovens - are a highly effective way to increase production capacity and line speeds.

When retrofit into an existing oven, as is often the case, no additional floor space is required. Catalytic infrared ramp ovens efficiently and precisely "preheat" the surface of the part. This enables the convection oven to work more efficiently, because part surface (and coating) are at optimum temperature the instant they enter the convection stage. Ramp ovens used in powder coating operations accelerate cure by gelling the powder prior to entering the convection heat zone for final cure. Key features of the Catalytic Infrared Curing Oven include a purge cycle before start-up, compliance with NFPA 86, and pre-assembled PLC-controlled gas trains that include gas pressure regulators, high and low safety switches, and modulating gas valves.

Heater zones are piped in loops for greatest uniformity of gas flow and pressure. Oven and controls are fully assembled and tested before shipment. Catalytic infrared ramp ovens are custom designed to the application. Systems are also engineered to production requirements, and curing specifications for waterborne, solvent-based and powder paint applications. They are a proven alternative for companies who need to maintain highest uniformity of powder distribution, and highest quality coating cure.

- increase production capacity

- precisely "preheat" the surface of the part

- oven and controls are fully assembled