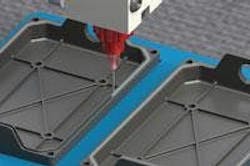

GA-201 Gasketing Resin

GA-201, a UV/Visible light-curable, tack-free, moisture and chemical-resistant FIP/CIP gasket for sealing heat-sensitive substrates such as plastic enclosures. Used as an alternative to tapes, PSA die-cut gaskets, 2K epoxies, silicone rope, or RTV sealants, it helps reduce labor costs and part handling while increasing production throughput. GA-201 can be easily dispensed into intricate and complex configurations and can accommodate design changes without investment in additional tooling. The material cures on-demand, eliminating the need for racking and the waste associated with poorly fitting or improperly aligned die-cut gaskets. GA-201 gasketing material acts as a barrier to prevent absorption or penetration of air, dust, noise, liquids, gaseous substances or dirt. It provides reliable protection, is easy to use (dispense and cure), cures without damaging heat-sensitive substrates, is cost-effective, and reduces process time and part handling.

- Cures with UV/Visible light

- Moisture resistant

- Chemical resistant

- Tack-free cure

- Soft, durable after complete cure

- Conforms to intricate channels and recesses

- Compliant with RoHS directives 2015/863/EU