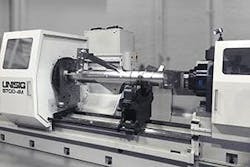

B700 Drop Bed Drilling System

UNISIG, the leading manufacturer of deep hole drilling systems and technologies, engineered its new B700 Drop Bed machine to effectively generate the critical, high-precision features on large and irregularly shaped aerospace components such as landing gear struts. Conversely, the extreme flexibility of the new machine allows it to also process medium sized, more uniform shaped workpieces with minimal changeover time from one to another.

The B700 offers an expansive working range with its servo programmable workpiece headstock capability, yet it sports a streamlined overall footprint that makes for space-saving installations and enhanced ergonomics. This is unlike other comparable deep hole drilling machines that are often inflexible dedicated systems as well as oversized and cumbersome.

Features:

- 63-in. swing over bed size

- handles parts as long as 157 in. or as short as 20 in.

- capable of internal contouring

- preloaded drive system

- 126-hp tool spindle

- 90-hp work spindle

- productively machines solid bores up to 8 in.; counter bores to 12 in. diam

- 250-gpm coolant flow