ANCA Obtains U.S. Patent for New Motor Temperature Control Technique

Melbourne, Australia-based machine tool builder ANCA has been granted a U.S. patent for Motor Temperature Control (MTC), a technique that dramatically improves the stability of precision machine tools.

The Problem

A key element of machine tools is the spindle which holds and drives the cutting tool which machines the workpiece. Any dimensional errors in the spindle will be reflected as dimensional errors in the workpiece. A common technique in modern machine tools is to use motorized spindles where the driving motor is an integral part of the spindle.

ANCA’s patent is a way of maintaining the motorized spindle at a constant temperature. A significant problem in the use of precision machine tools is the impact of changes of temperature particularly in the temperature of the spindle. Changes in the temperature of the machine tool can be caused by changes in ambient temperature, coolant temperature, run time, spindle rpm, and spindle load.

The Solution

ANCA’s solution is to actively control spindle temperature by varying the electrical losses in the motor element while simultaneously maintaining spindle motor speed and load. This is accomplished by using special firmware in the spindle drive amplifier. Although simple in concept, this in practice is a major step forward in manufacturing technology.

Examples of MTC Technology in Applications

Faster Warm-up time

A near-universal approach to precision machining is to run the machine in a warm-up cycle to bring all the elements of the machine to some level of thermal stability. Typically, this warm-up cycle will take approximately half an hour. Using MTC, this time can be reduced to around 5 minutes.

Figure 1 shows the impact of MTC on actively heating the spindle to reach working temperature quickly.

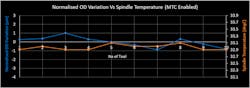

Stability in Batch Grinding of Endmills

Figure 2 shows the results of grinding two batches of 0.2 in. (6-mm) diameter endmills, with and without MTC.

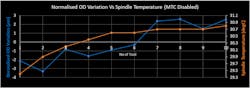

Grinding a Skiving Cutter

Electric vehicles incorporate a high-speed gearbox in their drivetrain. The accuracy of the components of this gearbox will impact on lifetime, efficiency, and noise of the electric vehicles.

Figure 3 shows a typical skiving cutter which is used to manufacture internal and external gears and will determine their accuracy.

ANCA manufactures a special machine, the GCX, for grinding this class of tools. MTC is a key enabling technology for this machine to produce cutters to AAA class.

Firstly, it's used to control the temperature of a dressing spindle which is used to create a high-accuracy profile on the grinding wheel. MTC is also being used to control the main grinding spindle temperature during up to 12 hours of continuous grinding.

Figure 4 shows the measurement results for the contour accuracy of a tooth and index accuracy for all the teeth.

Summary

Motor Temperature Control (MTC) is a major innovation in machine tool technology. It improves the accuracy and stability by controlling the temperature of motorized elements of the machine with special software in the spindle drive amplifier. It drastically reduces the time required for a machine to reach working temperature.

ANCA is a manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics, and medical.

Pat Boland is the Co-Founder and Managing Director for ANCA.