Programmable Sources, Loads Boost Manufacturer's Micro Inverter, Electric Vehicle Projects

With the current emphasis on carbon reduction, renewable energy is in the spotlight. Photovoltaic (PV) power sources are of particular importance because they can be scaled down to the level of microinverters for residential use or be deployed in remote locations to power electric vehicle (EV) charging stations.

Allied Market Research forecasts that the global micro-inverter market is growing at a CAGR of 19.7% and will reach $13.5 billion by 2030. Micro inverters, which often connect to a single solar panel, can optimize power transfer from the panels to which they connect, even if other panels in the installation are experiencing different levels of intensity and shade.

The firm also estimates that the solar EV charging market is growing at an 8.1% CAGR and forecasts that it will reach $330.9 million globally by 2031. The firm cites advantages such as energy independence, ease of installation, and improvements in energy storage systems as key drivers for this market. PV inverters, in general, present significant testing challenges.

Their test requires a solar-array simulator that matches the output I-V characteristics of solar cells. That requires a programmable DC power supply operating as a current source with a soft output characteristic—not the complex output characteristic of a typical DC power supply with large output capacitors, which strives to maintain its programmed output voltage under all operating conditions.

In a related manner, a DC supply used as a solar-array simulator must exercise the inverter under the test’s maximum power point tracking (MPPT) capability. MPPT enables the inverter to continually adjust its input characteristic to maximize power transfer from the PV panels it will attach to during regular operation. A panel’s maximum power point varies with irradiance levels, and an inverter with MPPT will alter its own input impedance to maximize power transfer.

To implement MPPT, many PV inverters, particularly micro inverters, impose an AC ripple on their DC inputs and monitor ripple voltage and current to determine the maximum power point quickly. A power supply used as a PV simulator must not filter out this ripple, as a standard power supply would because the ripple is critical to the execution of the MPPT algorithm.

In addition, an inverter test system must include a load on the inverter’s output—typically, a regenerative programmable AC power source that acts as a grid simulator. The grid simulator itself probably connects to the actual grid. It thus must meet anti-islanding safety requirements that mandate that it shut down within a specified time in case of an actual grid failure.

Finally, the inverter under test may be bidirectional. It may provide power from a PV array to the grid when the sun is shining and transfer power from the grid to a backup battery when not.

Solar-Power Product Test

One U.S.-based top-tier renewable-energy provider with a worldwide presence has called upon AMETEK Programmable Power for several test needs related to its various solar-power products.

First, the company needed to perform pre-compliance testing of a solar micro inverter and related battery-storage infrastructure for both residential and commercial installations in accordance with IEEE 1547, “IEEE Standard for Interconnection and Interoperability of Distributed Energy Resources with Associated Electric Power Systems Interfaces.” That standard applies to the interconnection and interoperability between utility electric power systems (the grid) and distributed energy resources (such as a PV inverter). It covers performance, operation, safety, and maintenance; it addresses responses to abnormal conditions, such as a grid failure necessitating anti-islanding; and it specifies test requirements for design, production, installation, commissioning, and ongoing periodic tests.

AMETEK Programmable Power proved to be the ideal partner for the company’s latest projects, having previously established a strong working relationship with its solar-inverter divisions and

battery-storage team. AMETEK Programmable Power has decades of experience with solar tests for space and terrestrial applications.

The company offers the TerraSAS PV simulators in the latter category, which provide low output capacitance and high closed-loop bandwidth to thoroughly test a PV inverter’s MPPT performance.

The company had previously purchased an MX Series source from AMETEK Programmable Power and had experienced the reliability and support the company could deliver. MX Series sources are available in single- and three-phase configurations with power ratings from 15 to 135 kVA. MX Series sources offer bi-directional regenerative operation with an automatic crossover between source and sink power modes.

The company chose to evaluate AMETEK Programmable Power’s new California Instruments Sequoia regenerative programmable source for its unique application with an e-load option for grid simulation. Compared with the MX Series, the Sequoia offered many incremental upgrades, such as higher output voltage ratings (up to 576V AC line to line) without needing an external step-up transformer. Voltages higher than 480V AC are often required for anti-islanding tests. Available in power ratings from 15 kVA to 1.08 MVA, Sequoia sources employ a state-of-the-art silicon-carbide (SiC) switching architecture and offer compactness, robustness, and reliability in floor standing chassis.

Sequoia also has a resistive, inductive, capacitive (RLC) load emulation capability. Compliance tests generally require a physical RLC load bank, but pre-compliance tests do not. Nevertheless, Sequoia’s RLC feature can help boost confidence that subsequent compliance tests will pass. Users can program resistance RLC load values into Sequoia, which will generate an RMS current with the appropriate phase angle per the programmed RLC values.

In addition, Sequoia has an external drive feature that allows an external analog signal to control the source, turning it into a high-bandwidth amplifier. This feature enables applications such as hardware-in-the-loop (HIL) tests to help study a PV inverter’s effect on the utility grid. Combining an HIL simulator with the Sequoia grid simulator results in delays of as little as 100 µs—essentially offering a real-time solution.

AMETEK Programmable Power was able to explain the benefits of the refreshed Sequoia grid simulation/e-load configuration clearly.

For example, Sequoia’s hardware-in-the-loop (HIL) capability and full RLC programming support could form a single-source solution for grid simulation and anti-islanding testing in accordance with IEEE 1547. Continuous on-site contact with the company’s sales and support partners throughout the evaluation process is helping to convert the company to Sequoia from legacy AMETEK Programmable Power products and competitive equipment

Micro Inverter Functional Test

The company also wanted to set up a functional and production test facility in Asia for micro inverters in the 800 to 1,500-W range, and it was looking for a PV panel simulator, grid simulator, and regenerative load. The PV simulator required a large-channel count capability in a compact, low-cost solution. In addition, space was a constraint in the existing lab. A full solar array simulator proved too costly and would take up too much rack space to meet the company’s needs.

However, the original design had been fully characterized and validated with a solar array simulator that could thoroughly exercise the inverters’ MPPT capabilities, so a simulator with the soft I-V curve that mimics an actual PV panel would not be required for the functional test. A power supply that could establish a constant-power characteristic from 120 V at 14 A to 100 V at 17 A would suffice.

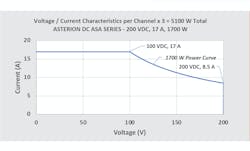

AMETEK Programmable Power’s Asterion DC ASA and ASM Series three-channel power supplies offered potential solutions. The ASM Series features the necessary 1,700 W per channel rating in a single 1U-high chassis, although it lacks the auto-ranging constant power capability the company requires. The ASA Series has wide auto-ranging capability but only carries a 600 W per channel power rating. However, AMETEK Programmable Power engineers could adapt the ASA through a firmware change to meet the company’s 120V at 14 A to 100V at 17 A specification, as shown in Figure 1. The company purchased 50 of the custom three-channel devices to meet its 150-channel needs.

Entering the EVSE Market

The company is also looking to expand into the electric vehicle service equipment (EVSE) business, complementing its microinverter and storage business and giving it full penetration into the energy management solutions market. As a new player in the EVSE arena, the company hired a team of engineers with automotive backgrounds who wanted a flexible solution for the design stage that could be adapted for functional and production tests while addressing all the components and subsystems that comprise the EVSE energy ecosystem.

Figure 2 outlines that ecosystem, which includes the grid itself, a stationary battery, a PV panel, a bidirectional storage inverter that charges the stationary battery from the PV panel or grid or that extracts energy from the stationary battery, the PV inverter, the charging station, and automotive components including the high-voltage battery and on-board charger, all of which require different types of tests and test equipment.

The company first addresses the charging station, which requires a programmable AC source to simulate the grid or inverter output. In addition, it requires a regenerative load to simulate the EV.

The grid and vehicle simulators must be bidirectional for vehicle-to-grid (V2G) applications, in which the vehicle battery provides backup power during a grid outage.

A key consideration for the company was that EVSE standards are evolving, and its engineers wanted test equipment sufficiently flexible to adapt. Some turnkey test systems on the market work for the current state of technology but may not be ideal in the future. The company’s engineers also needed flexibility to address R&D test requirements while maintaining a smooth transition path to functional and production tests. While the exact configuration of a production system has not been finalized, the company chose new Sequoia sources with regenerative load capability for its R&D initiative. The Sequoia can serve as both an EV emulator and a grid simulator, offering considerable flexibility as the company’s test needs evolve.

As with the microinverter PV applications, AMETEK Programmable Power’s early communication helped build trust within the company’s EVSE team, and this communication and support will continue as the company moves from R&D to production for its EVSE offerings.

Looking Toward a Renewable Energy Future

AMETEK Programmable Power is ready to apply its superior product quality and application expertise to your renewable energy products. AMETEK Programmable Power can leverage its decades of expertise and its refreshed next-generation products, such as the Sequoia AC sources and Asterion DC ASA and ASM Series supplies, to meet your programmable power needs.

The company offers a wide range of standard products and custom-engineered solutions to meet your exacting requirements.

Download this white paper in PDF format by clicking the download button below.