AI Consistency Used for Subjective Human Decisions

Product perfection is now an expectation for consumers, which places far more pressure on manufacturers to always deliver. Surprisingly, a great deal of quality control and inspection still relies on the human eye and subjective decisions.

When it comes to inspection tasks, humans do a pretty good job. We can rely on our senses to detect differences and even taste and smell depending on the product. If something changes, we’re adaptable and can make quick decisions on our own. We’re also pretty easy to train, and we learn by example.

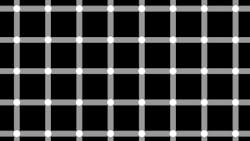

However, when we get tired, distracted or bored we start making mistakes. Our eyes can also trick us. For example, try to count the white dots in Figure 1. Traditional vision inspection has error rates as high as 30%. Often, what an inspector flags as an error is actually a false positive as they begin to doubt their own decisions.

The key advantage with technology—it can make decisions faster, consistently, and over and over without getting bored. Now with artificial intelligence (AI), machines can begin to learn and make their own decisions. Despite these machine advantages, there’s still a significant requirement for humans in inspection processes.

For manufacturers specializing in short-run, customized, seasonal, and regional products it’s often uneconomical to fully automate inspection processes. Premium and boutique brands also place a lot of emphasis on the human touch in their manufacturing process. For these manufacturers, AI-based visual inspection tools can help add decision support so an operator always makes the right, objective choice.

New AI-based tools for visual inspection take advantage of advances in edge processing and simplified algorithm development to help highlight product differences and deviations. For many manufacturers who have or are evaluating AI, model training and development pose significant cost and expertise barriers.

In comparison, new tools use operator input to help train the AI model. Using a basic image compare function, the system visually highlights possible product differences for an operator as they evaluate products against a saved “golden reference” image. As the operator accepts or rejects initial possible errors, behind-the-scenes the AI model is transparently trained and it will quickly begin suggesting if it thinks a difference is an error.

In addition, automated and customizable reporting tools help manufacturers gain data on visual inspection processes. Often, visual inspection poses a “data black hole” for manufacturers, which makes it difficult to ensure end-to-end quality and time-consuming to resolve issues when errors occur. For example, with these reporting tools, operators can capture images of manual inspected products alongside their notes and save the data to their manufacturing planning system.