A Comparison of Measuring Amplifiers vs. PLCs

New Concepts are Required

Frequently, the interaction between the individual parts of production systems or test benches has only been possible through complicated transfer channels and interface converters. To make these increasingly complex systems more efficient, there has been a consistent shift, over time, toward uniform interfaces and components taken as building blocks from a modular system. Similarly, product developers and production planners are looking for flexible systems that offer easy integration of new technologies, without users having to retrain each time. Hence, a fundamental distinction must be made between automation tasks and product development tasks. Product development requires precise data acquisition at high recording rates. In automation environments, sequences need to be run in deterministic real-time to optimize machine operation. In this case, measured data is less important than diagnostic data. The formerly separate fields of product development and automation have already been brought together in today’s mechatronic systems. Ideally, the components should provide sufficient flexibility to allow their use in both areas.

What does a PLC do?

A programmable logic controller (PLC) is a device that has been digitally programmed and is used to control a machine or system. In the simplest case, a PLC has inputs, outputs, an operating system (firmware), and an interface that enables the user program to be loaded. The user program determines how the outputs are switched as a function of the inputs.

In general, a PLC has a deterministic time behavior, i.e., cycle times are defined with millisecond precision for the processing of the user program and thus the machine's control sequence. Once it has been programmed, the PLC is a “docile workhorse”. Changes to the sequence, however, always demand a specialist who adapts or changes and validates the operating program. This requires long and sound specialist training.

The PLC is connected to the machine or system by sensors and actuators. In addition, there are status displays. The sensors are connected to the PLC’s inputs and convey what is going on in the machine or system to the PLC. Sensors include, for instance, probes, light curtains, incremental encoders, limit switches, temperature sensors, filling-level sensors, etc. The actuators are connected to the PLC’s outputs and enable the machine or system to be controlled. Actuators include, for instance, protective equipment for switching on electric motors, electric valves for hydraulics or compressed air, or modules for drive control (motion control, rotational-speed control with controlled acceleration or deceleration, and stepper motor controls).

Differentiation according to modularity

Modular PLC

The controller consists of individual components, each performing a different task. The simplest example would be a PLC comprising a central assembly for computing (including the main processor unit) and at least one input and one output assembly. These systems can be extended with additional assemblies if, for instance, more inputs or outputs are desired. Specialized modules, for instance, a module with a serial interface, also enable the integration of components such as weather stations. The processing of analog input signals, complex control modules, and many other modules can also be added.

Compact PLC

Compact controllers cannot be extended or can be extended only to a limited degree; however, they are more economically priced and space-saving. Apart from that, they offer the same basic functions as modular PLCs.

Applications and limits of a PLC

Using PLCs is recommended wherever a large number of digital signals and basic measured values supplied by sensors and actuators are merged in a central control cabinet. PLCs operate in a clock-synchronized manner in the previously created operating program to control machines and systems.

Creating and changing operating programs requires experienced programmers. Retrofitting and extending PLCs is, thus, a complex process, and the programs cannot be created and adapted without the support of specialists. This also applies to the smaller compact controllers that cannot be operated by laypersons without specialist knowledge.

The fixed cycle time limits the amount of data that can be processed by a PLC. This means that PLCs are quickly pushed to their limits when used for measuring and controlling tasks involving high data volumes that require precise measurement signal curves.

The accuracy of the I/O modules’ measured signals is often not sufficient to enable accurate decisions with respect to signals and processes in the system, which in turn minimizes the efficiency of the production and testing processes.

A PLC is to be considered as a self-contained system with an inadequate “external” connection via corresponding interfaces. However, an adequate interface is one of the main requirements of digitization and the IoT. Besides system control, other requirements now include cloud-based data storage, evaluation, and visualization to enable the desired leap in productivity.

Operation Technology (OT) and Information Technology (IT) are merging

The same applies to the testing and controlling software. Measured quantities from the test field must be saved and analyzed by suitable software. Due to the huge data volumes, this software is PC-based. The data is transmitted to a measurement PC via an Ethernet interface. Parts and methods of the evaluating software will later be used in the production environment and combined with parts of the control technology. In addition, a high degree of real-time behavior is often required for mechatronic systems in production environments to guarantee smooth, error-free interaction between all the components.

HBM offers an integrated concept for sensors and measurement acquisition for both development and production. Besides providing suitable sensors, modern testing and measuring components are at the heart of this production measuring chain. However, existing PLC systems are often not capable of keeping up with the requirements of modern and highly dynamic production lines, owing to the fact that they do not have the required capacities. The important criteria for successfully using this type of measurement system include data transfer in real-time, high computing capacities, and, not at least, simple parameterization and visualization of measured data for different groups of employees and operators.

Smart measuring amplifiers as components used in testing and measuring and as data loggers

The fast, precise and noise-free collection of measured data runs at a sampling rate of 20 kHz. The TEDS sensor identification simplifies the amplifier configuration and measuring due to the fact that the measuring amplifier automatically identifies the connected sensor and is configured to match its measuring and operating range. The measured value status enables diagnostics to be run channel by channel in the measuring amplifier. This allows for targeted interventions–both on-site and by remote control–in the event of disturbances.

Smart measuring amplifiers with internal calculation channels (SMART functions)

To operate an automation system in a stable manner, the transfer channels must not be "jammed". This means that as much of the measured data as possible should be decentrally pre-processed in advance. To achieve this, the component needs to have internal calculation channels that perform monitoring and controlling tasks in real-time. The signals can be further processed internally or output to the automation system via analog outputs and fast, Ethernet-based fieldbuses. This does not overload the machine/system controller and short, fast control cycle times can be achieved. To achieve this, the computational functions have been predefined and can be combined by the user by mouse-click. Using this type of measuring component, the task to be performed is parameterization instead of programming, which can be easily done without having completed a special programming training.

New communication channels allow intuitive operation and signal transmission

Users and system operators use smart devices on a daily basis. Modern automation components have made measuring and testing technology more convenient – software and operating technology only known in smartphones and tablets up until now. Standardized interfaces also provide easy access to all device parameters for configuration, operation, and analysis, via any Internet-compatible terminal device. This results in a secure and future-proof investment for the user.

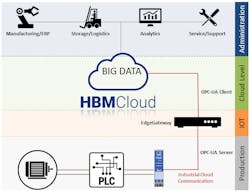

Edge computing facilitates the smart factory

Edge computing refers to distributed data processing at the edge of a network. A physical edge device collects, filters, and analyzes data. It acts as the interface between Operational Technology (OT) on the machine level and Information Technology (IT) on the corporate level and further on into the cloud. Edge devices enable the mastering of many challenges as they do not require any intervention into control architectures that have grown over decades, which would involve high expenditure and the risk of a loss of production. Furthermore, the comprehensive operational and process data can be pre-processed, and the device operates as a multi-protocol communication interface between the machines and the corporate servers.

Edge controller networks

Using modern testing and measuring equipment as edge devices opens up the world of IoT to machine builders. I/O assemblies enable the sampling of additional signals via analog and digital inputs, which allows for predictive maintenance. An edge controller supports various communication protocols (SMB, OPC UA, TSN, and MQTT) that enable all the required units to be horizontally and vertically connected to form a smart factory. It also allows cloud connections to be implemented. Integrating potential future protocols is not an obstacle as well. In this context, it is important that all the system interfaces allow non-reactive access to all the components.

New interface protocols are required

A new data format is required to enable the efficient transmission of the planning and diagnostic data in production to the cloud. This new format, OPC-UA, is based on its predecessor, OPC, and has now been standardized and established as the global standard. OPC Unified Architecture, in short, OPC UA, is an industrial machine-to-machine communication protocol. OPC UA is the latest OPC specification developed by the OPC Foundation, and it differs significantly from its predecessors, particularly because it enables machine data (control variables, measured values, parameters, etc.) to not only be transferred but also semantically described in a machine-readable form. This technology, too, is Ethernet-based and offers great potential for savings and investment security. The data is sent through Ethernet as well; however, the cycle is slower than that with fieldbus systems.

Fields of application and limits for the users of automation components based on testing and measuring equipment

These components such as ClipX and PMX from HBM ensure that the required increased measurement accuracies and high sample rates are achieved even in the partial load range. They are in line with the trend toward increasing production and analysis quality. Only if all the sensors of the measuring chain as a whole comply with these requirements can an accurate quality assessment be made later. To achieve this, the measuring hardware must provide the appropriate measuring and signal quality.

Conventional programmable logic controllers (PLCs) cannot achieve the required quality. This can only be done with measuring amplifiers such as ClipX or PMX that have high signal resolution (24bit) and an insensitive converter input stage. The carrier frequency method is recommended for this purpose: The measurement signals are first modulated and then amplified. This eliminates system-induced interference effects such as AC hum and thermoelectric voltages. Please note: All the measurement channels, regardless of their configuration level, are recorded in parallel at a sampling rate of 19200Hz.

The new network and communication technologies implemented in the smart measuring amplifiers make processes leaner and more transparent. Production and test-bench control become easier since it is extensively automated and can be remote-controlled. Deployment of considerable manpower and staff training is no longer necessary. The systems report on their “health”, and maintenance can be optimized accordingly.

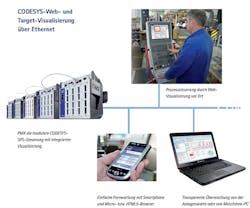

The PMX measuring amplifier system provides maximum flexibility since, owing to its integrated CODESys Soft PLC in compliance with IEC61131, it is turned into a control system itself and is capable of transmitting in parallel and saving its measurement and analysis data to a quality computer or to the cloud. This automatically turns the PMX into an automation and data acquisition system.

The ClipX and PMX measuring amplifier systems can also be optionally fitted with the Profinet, EtherCAT, or Ethernet/IP fieldbus types to connect the system to the production level. The systems enable sensors and actuators to be connected. These connections are monitored by additional diagnostic data, and disturbances can be signaled in real time. In addition, the pre-processing of the measured data in real-time is possible. A substantial part of the plant controller’s system load is pre-processed in the ClipX or PMX, lessening the PLC’s work.

Major new options can be opened when system data is stored and used centrally. This is now applied to production in the same way as in cloud solutions such as Google Maps. On one hand, special requirements such as production control based on batch sizes and material procurement can be laid down. On the other hand, irregularities can be detected, signaled, and avoided more easily. Production becomes more efficient, cost-effective, and largely automated. Manual processes become superfluous and maintenance can be controlled as needed.