How One Small Company Mastered the 3D Printing World

CS Hyde's move into the additive manufacturing market teaches a powerful lesson on flexibility, ingenuity, and listening to your customers.

For the past 20 years, CS Hyde has been serving up variety of tapes, films, and fabrics to both private and OEM customers around the country.

Browsing its product line up, you find generally what you would expect from a company like this-a lot of plastics and laminations, adhesives and films, a lot of 3M products and the like.

But there is one exception.

Mixed into CS Hyde's standard lineup of product categories is a new section dedicated solely to 3D printing.

This category stands out on the list, sure, but it also makes perfect sense if you know the 3D printing industry.

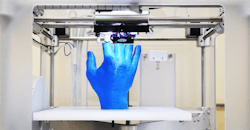

One of the biggest issues in 3D printing, particularly for home-use equipment, is getting the finished object off the build plate when it is done.

Remember, the 3D printing process includes basically drawing molten plastic down onto a metal sheet. When it dries, it can be tricky to remove in one piece—and that's putting it lightly.

To deal with that, printers often resort to covering the plate with tape or lathering it in hairspray to help loosen the bond.

CS Hyde, though, has been selling a full line of coatings perfect for this job for decades.

It's a perfect match for this industry, really. So the pairing isn't terribly surprising in itself.

What is surprising, however, is how such a small company out of Lake Villa, Ill., specializing in custom die cutting and lamination, was able to carve out such a comfortable niche in one of the biggest tech revolutions of our day.

The story behind it provides a good lesson on innovation for us all.

To tell it, we connected with Tiffany Hoerle, Vice President of CS Hyde.

A typical tape-job on a 3D printer's build plate.

NED: How did you get into the 3D printing market?

HOERLE: It was completely, purely by accident.

We came into this from home users-guys that are making their 3D printers in their basement or their garage. Engineers tinkering with equipment at their homes.

We worked with a couple of these guys who were fiddling around with different materials that are relevant to the release of the filament from the print surface.

They approached us and asked if we had something like that. Sure we did.

We had these standard products with an adhesive on it we sold in rolls for completely different, very industrial applications.

So we worked with them, tried a few different adhesives and then found two or three that work wonderfully.

Then we thought, who else is using this? Is there a market here?

So we started to do some research and got out there and talked to a couple more people. It has been growing ever since.

NED: What exactly did these users need?

HOERLE: Originally, it was for the Ultem PEI. Basically, it's a high performance plastic that has been around for a very long time. We've been supplying it in some form for over 12 years. It's not made for the 3D printing industry, it just happens to work for this application.

One of the main reasons why ULTEM is so great is there is no surface prep. You literally just print on it; you just go. You don't have to rough up the surface, you don't have to smooth the surface. It's perfect.

CS Hyde offers ULTEM 3D printing materials in a range of 0.001 to 6 in. thick, cut to standard or custom sizes in order to fit every 3D printer's needs.

NED: This seems like a huge jump. You went from taking a few inquiries from a few private users to marketing a whole line of 3D printing materials. How are you structured to make that move?

HOERLE: We are a small company, so it's a lot easier to be able to implement and work with customers on a more custom basis. We don't have a lot of hoops we have to jump through to be able to service our customers and really sit down and listen to them, take their suggestions and try things out.

The great thing is, we already had all of these materials here. It was just putting different materials together and coming up with something new that we are getting a great response on.

This is kind of what we do here.

A long time ago, like 15 years ago, we had some rolls of Teflon tape out on the website listed as excess stock. Our slitter had cut the wrong size and we had nothing we could do with them.

So we just put them out there and we started getting some requests from individuals, even though we didn't really sell to individuals at the time.

They wanted to use them for what they call mouse tape. It's something that gamers like to use.

Back at the time, we thought that was interesting. We asked, what else can we do with this?

Then we started die cutting some different materials and offering it in a better shape to fit on the mice. And then we came up with a mouse pad that the computer gamers really liked.

It's kind of what our company has really done from the beginning. We always try to work and listen closely to our customers to try to provide them with a solution or to provide them, within our abilities, whatever we can.

NED: So, to stay on top of the new trends, you have to listen to your customers and be flexible enough to adjust to them?

HOERLE: It's just like anything in the industrial world. There are always new things popping up.

They might be small and not have a significant impact, but it's forever changing. The industrial world is not what it was back in the '60s. It's just not the same space anymore.

So companies need to evolve with it.

At CS Hyde, we hit our 20 year mark this year, and I've been with the company for 19 of those 20 years. Just seeing how this small little company has evolved in those 19 years, and how the industry is has evolved, is amazing.

We as a company have to evolve along with different markets that we serve.

We try our best to do that; we truly do.

About the Author

Travis Hessman

VP of Content, Endeavor Business Media

Travis Hessman is the VP of Content for Endeavor Business Media. Previously, Travis was the Editor-in-Chief for Industry Week and New Equipment Digest as well as the Group Editorial Director for Endeavor's Manufacturing Group.

He began his career as an intern at IndustryWeek in 2001 and later served as IW's technology and innovation editor. Today, he combines his experience as an educator, a writer, and a journalist to help address some of the most significant challenges in the manufacturing industry, with a particular focus on leadership, training, and the technologies of smart manufacturing.