Intelligent Design: Lotus Leaf Inspires Anti-Microbial Metal

If you’re having trouble designing a material to repel biological threats, such as pesky disease-causing microorganisms, remember humans have been around less than 100,000 years, while bacteria have been around for more than 3 billion. Don’t worry though. Nature has done waaay more R&D than you, and an elegant solution for the single-celled invaders has already been found in the composition of the lotus leaf.

The Lotus leaf is nature's Rain-X.

From the ancient Egyptians to Buddhists monks, the lotus has been revered for the geometric beauty of its flower to its stalwart lifecycle. In the 1990s, UCLA researchers recovered a 1,300-year-old lotus seed from a barren Chinese lake bed that was still viable, and in a totally Californicating way, have sequenced its genome to try to break the spell of aging.

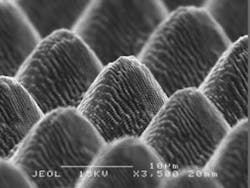

You don’t have to go DNA-deep to find out how the self-cleaning Lotus can shake off beads of water or bacteria. An electron microscope would help, though. That way you can see the Lotus leaf’s “rocky” surface at the micron level. The super small pockets created by the rough micro-topography create a buffer of air that prevents liquids from sticking to the surface, and material scientists have mimicked the hydrophobic “lotus effect,” discovered in 1997, for paints and other materials.

This summer, a European research team, led by Luca Romoli, a professor at the University of Parma in Italy, announced advancements to replicate the lotus effect on stainless steel by etching it with a laser 156 times faster than previously capable, making it the world's first self-cleaning metal.

Known as TresClean, the Photonics21-funded project could drastically reduce costs — and the spread of bacteria — in food production facilities across the globe by making surfaces and conveyors more sterile. It may even end up in home appliances such as dishwashers, or hospitals in the form of surgical tools.

“Bacteria do not get a chance to stick because the contact with the metal surface and the liquid is reduced by over 80%,” Romoli says. “We are looking at an anti-bacterial metal."

In facilities where Listeria and other bacteria can fester, and considering more and more are becoming antibiotic-resistant, implementing self-cleaning stainless steel can prevent business-killing recalls, and death in general.

"Infections by pathogenic microorganisms adhering on various surfaces kill worldwide more people than any other single cause," Romoli states.

The NIH backs that up, citing that bacterial infections (streptococcus and salmonella, for instance), are among the leading causes of death globally.

And this TresClean method could etch nano-craters in metals used near food or hospitals, or even on the ultimate germ magnets, doorknobs, to resist these bacteria at an industrial pace.

The innovation here is the high throughput laser capable of etching the biomimetic design at a rate of 1,000 sq. cm/hour, whereas previous methods could achieve 1 sq. in./hour.

"The laser setup that we hypothesized is based on the synchronization of ultrashort pulse lasers with fast scanning technology -- from RAYLASE AG -- for beam movement of 200 m/s and high throughput production," Romoli explains.

Commercialization is at least two years away, though Romoli has said several companies have already reached out.

Once that happens, Romoli believes it will offer major production advantages to users.

"Vats in milk factories need to be cleaned every 6 to 8 hours to avoid the exponential growth of bacteria," he says. “This hinders usage and therefore affects output."

By saving hours per day in cleaning, it will yield an efficiency improvement stemming from fewer sterilization cycles and less cleaning time within production as a whole," the researcher continues. "This will also reduce energy consumption as a result of fewer cleaning phases making food production quicker, safer and more profitable”.

About the Author

John Hitch

Editor, Fleet Maintenance

John Hitch, based out of Cleveland, Ohio, is the editor of Fleet Maintenance, a B2B magazine that addresses the service needs for all commercial vehicle makes and models (Classes 1-8), ranging from shop management strategies to the latest tools to enhance uptime.

He previously wrote about equipment and fleet operations and management for FleetOwner, and prior to that, manufacturing and advanced technology for IndustryWeek and New Equipment Digest. He is an award-winning journalist and former sonar technician aboard a nuclear-powered submarine where he served honorably aboard the fast-attack submarine USS Oklahoma City (SSN-723).