A Revolutionary New Approach to Mechanical Testing

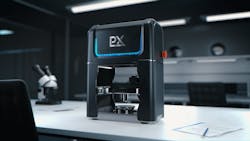

Plastometrex's newly launched Indentation Plastometer is a macro-mechanical test machine that measures full stress-strain curves and metal strength parameters from a simple indentation test. The Indentation Plastometer combines the simplicity of testing with the acquisition of full stress-strain curves and material strength characteristics. The machine works by pushing a hard spherical indenter into a test piece under pre-programmed testing protocols, followed by measurement of the residual indent shape using an integrated profilometer. The measured shape data are then analyzed in a proprietary software package that converts the residual profile shape into a stress-strain curve in a matter of minutes.

Plastometrex was founded in late 2018, but the technology is built on more than ten years of prior research work conducted at the University of Cambridge. In fact, the company was co-founded by Professor Bill Clyne, an Emeritus Professor at Cambridge and the current Chief Scientific Officer. Bill co-founded the company with several of his former Ph.D. students, and since its founding, the company has raised almost $2m of investment, with Element Materials Technology (one of the world’s leading providers of testing, inspection, and certification services) leading the company’s most recent seed investment round.

Our mission is to make mechanical testing simpler, quicker, and more convenient, to provide our clients with material insights not otherwise obtainable, and to collect, process, and analyze testing data to drive improvements and efficiencies in the products and processes. In fact, in a recent poll of industrialists interested in mechanical testing, slow testing turnaround times was the most commonly cited problem—way ahead of materials testing costs. We’ve developed a mechanical testing system that can measure metal stress-strain curves in under 3 minutes. Minimal sample preparation is needed, real components can be tested, and the process is intuitive and fully automated. The underlying technology can be deployed in a wide range of test configurations, allowing full integration with existing plant and industrial process systems. The ability to test, measure, and qualify materials and components in almost real-time unlocks entirely new business models and builds a strong competitive advantage.

Since its launch in November 2020, Plastometrex has shipped units to the United Kingdom, North America, and Germany, where the machines are being used to support testing requirements in the defense industry, in R&D departments, and in university research laboratories including Oxford University in the U.K. and the Worcester Polytechnic Institute in the U.S.

The benchtop system is gaining traction for high throughput testing, combinatorial alloy development, testing of small samples that cannot be tested using conventional machines, forensic failure analysis, pre-release testing, and testing of additively manufactured components, amongst others. “We’ve been pleasantly surprised by the high levels of interest we’ve been able to generate in a relatively short space of time—especially at a time when many companies are taking stock of their positions or rationalizing their operations for post-COVID market conditions. I think this reflects a genuine need for a technology like ours which gives our users almost immediate access to the strength of their materials, without the need to machine complex-shaped specimens, and without the need to ship those specimens to an external testing house. What has worked well for us so far is our participation in industrial trials with potential clients, where we confirm through blind trials that our technology works on their materials. We strongly encourage interested companies to reach out to us directly to request their own industrial trials," says Plastometrex CCO, Dr. Mike Coto.