Finnish Company Raises $4M to Advance Magnetic Levitation Bearings

SpinDrive, the Finnish company providing affordable, active magnetic bearings for original equipment manufacturers (OEMs), has secured a €3.8M (~$4.1M) Series A funding round.

The round was led by U.S.-based, hardware-focused investor Rhapsody Venture Partners, with existing investors Innovestor from Finland and Born2Grow from Germany also participating. The funding will enable SpinDrive to ramp up its commercial growth and improve industrial efficiency in factories worldwide.

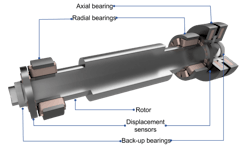

SpinDrive’s frictionless bearings are small, energy-efficient, and tend to be more affordable than others on the market. Working through magnetic levitation, the bearings ensure no contact between rotating and stationary parts. Since there's no friction, there's no bearing maintenance for up to 20 years—according to SpinDrive. The company even stands by this when talking about high-speed applications, meaning customers can achieve high rotational speeds with energy efficiency— all without the risk of downtime or maintenance breaks. When looking at traditional ball bearings in high-speed applications, they have a 12 to 18-month maintenance cycle which requires bearing replacement. So you're replacing bearings at the least every year and at the most, every year-and-a-half.

SpinDrive’s bearings also provide condition monitoring and predictive maintenance of the entire machine, removing the need for external sensors to monitor system health and reducing overall maintenance costs.

The bearings don't need oil to work either, removing the need for polluting lubricants from production. Since traditional machinery suffers from high leakage and contamination risk from lubricants, having a lubricant-free option makes production more environmentally friendly and allows manufacturers to enter into new markets like food & beverage, pharmaceutical, semiconductors, or hydrogen-based production where hygienic, contamination-free processing is essential.

Another advantage is the energy-saving capability of bearings. For example, large machinery operating at 100 kW to several MW requires considerable energy, and ball bearings limit machinery efficiency due to friction. Traditionally, OEMs using AMB technology have been restricted by its size, cost, and complexity. By providing an affordable solution to overcome these limitations, SpinDrive’s AMBs and controllers enable energy needs to be reduced by as much as 15% by allowing increased rotational speeds in many different systems that weren't previously possible. This is a significant saving, as industrial electric motors currently account for 46% of the world’s electricity consumption.

Improved energy efficiency is a key element in reducing industrial emissions. SpinDrive sees CO2 emission mitigation as one of its most significant contributions, and the company aims to help cut 500 Mt of CO2 by 2050 annually by improving the energy efficiency of industrial machinery.

“Climate change is the biggest challenge of our time, but we often get stuck thinking about technologies like carbon capture when it comes to CO2 emissions. Industrial production is a massive part of the world’s energy consumption and climate emissions, so we must create energy-efficient and clean components to turn this tide. By improving the energy efficiency in existing and new machinery, we tackle the problem in a massive area and provide a significant impact,” adds Janne Heikkinen, CEO and Co-founder of SpinDrive.

SpinDrive’s typical applications include turbo blowers, compressors, expanders, process machinery, flywheels, and energy recovery systems. High rotational speed yields high energy efficiency in transferring and compressing gases with turbo machinery, and frictionless operation cuts energy losses of spinning rotors.

“We scour the world for great hard science breakthroughs and love innovations that sell. SpinDrive’s system is much cheaper and better than anything else on the market. We are excited to partner with the team and to help grow SpinDrive internationally,” says Carsten Boers, Managing Partner at lead investor Rhapsody Venture Partners.

The company has raised a total of €8M (~$8.6M) to date from a syndicate of VCs and private investors, as well as public funding. SpinDrive has the most advanced control systems for active magnetic bearings, with customers in Finland, Germany, the USA, Denmark, France, Italy, China, and the UK. The company has offices in Finland and Germany. SpinDrive has seen significant improvements in efficiency in its cooperation with current clients, such as global pulp and paper vacuum solutions provider Runtech Systems.

“Active magnetic bearing technology is a major leap towards more sustainable papermaking, with a very affordable total cost of ownership. 1 MW unit offers an unbeatable small footprint and material efficiency combined with low energy consumption over the product's lifetime. We look forward to deepening our cooperation with SpinDrive and continuing the application of Magma AMB controller in other machine models,” says Ville Lahdensuo, R&D Director at Runtech Systems.

SpinDrive was founded in Lappeenranta, Finland, in 2015 to commercialize magnetic levitation solutions for high-speed machines. SpinDrive’s vision is to become a world leader in advanced magnetic bearing solutions with IoT condition monitoring by increasing efficiency and reducing costs and maintenance in industrial bearings. The company aims to help mitigate CO2 emissions by 500 Mt by 2050 annually and remove polluting lubricants from industrial production while ensuring profitability and reducing running costs.

SpinDrive has raised a total of €8M to date from a syndicate of VCs and private investors, as well as public funding. The company has customers in Finland, Germany, the USA, Denmark, France, Italy, China and the UK. SpinDrive has offices in Finland and Germany. For more information, visit www.spindrive.fi or follow us on LinkedIn.

About the Author

Laura Davis

Editor-in-Chief, New Equipment Digest

Laura Davis is the editor in chief of New Equipment Digest (NED), a brand part of the Manufacturing Group at EndeavorB2B. NED covers all products, equipment, solutions, and technology related to the broad scope of manufacturing, from mops and buckets to robots and automation. Laura has been a manufacturing product writer for eight years, knowledgeable about the ins and outs of the industry, along with what readers are looking for when wanting to learn about the latest products on the market.