Highly Automated Shot Blasting for Transmission Components in EVs

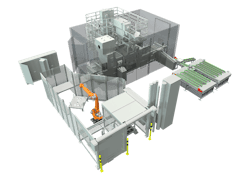

For the expansion of its transmission production facility for electric vehicles, a German automotive supplier purchased a new continuous feed blast machine from Rösler that includes fully automatic workpiece handling.

The customer chose the Rösler equipment because it offered high productivity, easy maintenance, and long service life. The OEM had previous experience working with an identical shot blast machine, which also helped them decide.

The workpieces in question consist of various toothed components for the transmission in electric vehicles. They must be deburred by shot blasting after undergoing a machining and subsequent heat treatment operation.

For this manufacturing stage in its transmission production facility, the manufacturer had to invest in a new shot blasting system. In 2016 the same OEM had already purchased a shot blast machine for a similar surface treatment task. In both cases, the customer chose a continuous-feed, wire mesh belt blast machine with largely automated workpiece handling from the Rösler Oberflächentechnik GmbH.

The company preferred the Rösler equipment over others because of its high productivity, compact automation, easy maintenance, and sturdy design.

Consistent, Reliable Deburring With Short Cycle Times

At the start of the deburring operation, the workpieces are manually placed on two storage units, which are part of the workpiece transport system.

After an integrated camera system has confirmed the correct transport position, the components are precisely positioned on the wire mesh belt in lots of three and continuously transported through the shot blast machine.

Upon completion of the shot blast process, a powerful blow-off system completely removes any residual blast media from the workpieces. In the next step, the now deburred components are transferred onto a buffering station consisting of a conveyor belt.

Here the workpieces are precisely repositioned so that a robot can pick up four pieces at a time and place them in layers into suitably staged workpiece bins. Whenever a layer is complete, the robot picks up an intermediate cardboard sheet and places it in the bin.

Completely filled or, in case of a workpiece change, partially filled bins are automatically removed from the robot working area. This allows the operator to safely remove them from the manufacturing cell with a lift cart.

Whenever the workpiece type changes, the operator selects the new type in the HMI. This causes the machine control to empty one of the two storage units of the workpiece transport system so that new parts can be immediately placed on the now-empty storage unit.

At the same the machine control selects the respective shot blast parameters for the new workpiece type. This ensures perfect deburring results and prevents any input errors by the operator.

The Goal: Short Cycle Times in Three-shift Operation

The shot blasting machine was designed for three-shift operation allowing cycle times of less than eight seconds per workpiece. Equipped with four high-performance blast turbines with an installed power of 11 kiloWatts each, the machine provides ample firepower to achieve the required deburring results.

The precise placement of the turbines on the blast chamber was determined with special software allowing the simulation of the blast pattern for the entire workpiece range. This ensures that all workpiece sections are reliably deburred within the required cycle time.

Easy Maintenance and Long Equipment Life

To guarantee long uptimes and very little work for maintenance, the turbines are completely made from carbide steel. The same material was utilized for the blast chamber sections exposed to a higher risk of wear.

To facilitate maintenance and minimize non-productive idle times, these sections are lined with replaceable carbide steel plates.

The turbine type and blast chamber design of the existing and new shot blast machines are practically identical. This greatly facilitates the maintenance and supply of spare parts by the internal maintenance department.