On-Demand Complex Metal Part Production

(Download this article in .PDF format by clicking the download button at the bottom.)

Additive Solutions Rooted in Subtractive Origins

Azoth specializes in manufacturing precision parts by leveraging production-capable additive technologies. The team’s experience is rooted in the optimization of traditional production processes; The company’s origin story starts with application and process engineers managing subtractive manufacturing lines to efficiently and repeatedly make parts to tight tolerances.

Azoth was founded by Scott Burk, Cody Cochran, and Jay Mullick from that experience with the idea to disrupt traditional manufacturing with 3D printing. Traditional production manufacturing processes, such as machining, investment casting or metal injection molding (MIM), often involve long lead times to design and fabricate tools, causing weeks-long production delays while waiting for an initial prototype.

Azoth uses binder jet 3D printing on the Desktop Metal Shop System to create prototypes, run pilot builds, and go to production all on the same machine without tooling. This allows Azoth to shorten lead times for metal parts from as long as four weeks to just 10 to 15 days, while also printing multiple iterations, allowing for faster testing and design refinement.

“We differentiate ourselves from service bureaus or job shops by taking a hands-on partnership approach with digital solutions for customers,” said Cody Cochran, Co-Founder and General Manager. The company prides itself on offering holistic support for customers at every step of the product lifecycle, from concept to product development and production. With its vertical integration, Azoth can design, manufacture, heat treat, polish, and deliver finished parts to specification all in-house and also perform mass customization at no additional cost or production time.

In addition to their fundamental understanding of conventional manufacturing production, the team has collected experience on a variety of additive processes. The company started working with polymer 3D printers, but soon it was clear that metal machines were necessary for metal end-use components.

Previously, parts from each product development stage were made using different technologies: prototypes were printed on SLS machines, pilot runs machined, and final runs produced via MIM. Using various processes meant quality control testing was needed at each stage and prototypes were only useful for fit and function.

Azoth’s metal 3D printing journey started with the office-friendly Desktop Metal Studio system that allowed the company to quickly get started printing metal parts without the need to handle metal powders. “We proved parts out in polymer and made metal prototypes on the Studio system, but we landed on binder jetting because of the surface finish, quality, and volume of metal parts we could produce,” Cochran said.

After building a good relationship with Desktop Metal and seeing increased demand for higher quantities and designs that were difficult to execute with the entry-level bound metal deposition Studio System, Azoth added the Shop System to its existing binder jetting portfolio to introduce higher volume production capacity. With the Shop System, every stage of a customer’s additive journey can be completed on the same machine.

“We can actually develop testing data on the prototypes because development and testing are happening on the same equipment used for production,” Cochran said.

Today, Azoth is able to deliver manufacturing solutions that bring value to its customers with a comprehensive understanding of the seven different types of additive processes recognized by ASTM and manufactures every complex precision metal component to a blueprint.

Take One Make One Digital Inventory

Beyond a production method for complex metal parts, Azoth uses 3D printing as a comprehensive supply chain management solution. Through the advanced manufacturing enabled by platforms like the Desktop Metal Shop System, Azoth empowers its customers to convert physical inventory to digital inventory and produce parts as needed without a minimum order quantity to justify up-front tooling or setup costs.

This Take One Make One (TOMO®) strategy helps eliminate supply chain disruptions by enabling qualified production of metal components on demand. As one part is taken out of inventory, another is made to replace it. With binder jetting technology, Azoth can change the order size as needed for responsive production while ensuring part quality and repeatability.

Establishing a digital inventory system creates a redundant supply chain that is agile and localized, allowing customers to reduce the carrying costs and storage of inventory as well as the long lead times of replacement parts.

“It’s the end-use version of a digital inventory and it’s the leanest supply chain possible,” Cochran said.

The team uses its broad manufacturing knowledge to help companies identify what can, and what should, be 3D printed.

“We play a big educational role to help customers learn what it looks like to set up a 3D supply chain. We’re talking to customers about what could be 3D printed, sometimes for main production and sometimes as a backup. But we work with them to get it into the validation stream early,” Cochran emphasized.

Even if 3D printing won’t be the mass production method, if it’s a consideration for future backup or service part production, Azoth stresses the importance of qualifying 3D printed metal alongside the traditionally produced part during development. By doing the same qualification, assembly, and testing with 3D-printed parts, a company can avoid repeat costs for testing setups while establishing trust in the 3D-printed components of the future.

Those part numbers are then added to the digital inventory and 3D printed to spec on-demand, significantly reducing both material and inventory waste. As a result of the TOMO strategy adoption, Cochran says Azoth typically delivers additive parts that are replacing traditional manufacturing processes.

Why Desktop Metal?

The Shop System’s use of binder jetting technology, compared to the Studio’s bound metal deposition, provided Azoth with benefits such as increased throughput via area-wide printing, design flexibility, and low-cost material options. Similar to an office printer with an inkjet head that deposits ink onto paper, in this case, liquid binder is jetted onto a metal power bed to bond the particles together in precise and complex geometries. This repeats layer by layer as fresh powder is spread and bound together until the final geometry is complete to form a green state part that is then sintered into a metal part.

Using the Shop System, the company can easily meet the throughput requirements its customers demand while maintaining low per-part costs with faster lead times than traditional manufacturing. The inherent design freedom of binder jetting technology also allows Azoth engineers to create unique parts that address customers’ specific needs. Using the Shop System, Azoth manufactures end-use parts for many industries and a variety of different applications, from custom shift knobs for automotive customers to firearm optic mounts and everything in between.

Application Examples

Physical NFT

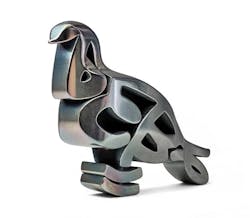

This part is a physical NFT, or non-fungible token. Most typically associated with digital artwork, NFTs are unique—hence the non-fungible part of the name—tokens that exist on a blockchain, meaning they cannot be replicated. Items like this are used to represent the digital token, making it easier to buy and sell digital tokens and reducing opportunities for fraud.

The complex design of this token made traditional manufacturing impractical and creating a mold or machining setups to produce this part would erase its unique nature as an NFT token.

Using the Shop System, this complex design was easy to print using 316L stainless steel before it was then polished and coated for aesthetic purposes.

Firearms Optics Mount

This part is used to mount an optical accessory on the slide of a firearm.

Due to the relatively low volumes needed for this part—only about 1,500 pieces are produced annually—the manufacturer could not justify the cost of creating tooling or complex machining setups.

Using the Shop System, however, the company was able to not only produce the required parts but also incorporated new features and reduced post-processing requirements. The design freedom of 3D printing enabled a hex pattern for lightweighting and reduced material usage—without the need for any extra machining steps or increases in build time.

Threads were also printed directly into the part for mounting, further reducing the need for additional machining. Aside from a blasted finish for aesthetic purposes, these parts are ready to use straight from the furnace.

Custom Shift Knob

These custom shift knobs were designed with an advanced spiral lattice that could only be created using additive manufacturing.

Binder jetting is the only method that is able to produce this geometry at the desired price point, because of the high throughput available through the Shop Systems' large build volume and unparalleled productivity that would allow Azoths to print a build of 54 of these parts in 10 hours.

This part and other parts like it are printed in 316L and feature printed threads and functioning safety lockout mechanism for the shifter.

These parts will be used as aftermarket parts on vehicles being built for SEMA (Specialty Equipment Market Association), one of the premier automotive specialty trade shows in the world.

Bolt Placement Grippers

These grippers are installed into a robot arm to pick and place bolts on an assembly line—thousands of pieces per day. While these parts look like they would be simple to machine, the intricate teeth in the design would require fine-detail machining and multiple tool switches to complete.

“These grippers are the perfect TOMO example,” Cochran said. “They are more cost-effective with binder jetting and can be delivered with a 10-day turnaround vs an eight-week lead time.”

Using the shop system for mid-volume production, Azoth is able to produce 1,400 of these end-use parts per day in 17-4PH heat treated to H900 to replace the traditionally machined tool steel components.

Growing the Business With Metal 3D Printing

Azoth’s mission is simple: to provide quality end-use parts as needed for customers. Building on its success integrating metal 3D printing with the Desktop Metal Studio System, the Azoth team today uses the flexibility of its Shop System to work closely with customers and design custom parts at a fraction of the time and cost needed for traditional processes.

The system’s speed and resolution allow Azoth to produce hundreds to thousands of tooling-free components with properties comparable to those created via traditional processes, like casting or MIM, and that can be post-processed in a variety of ways to meet customers’ needs.