Key Differentiators to Optimize Polarization Controllers

Download this white paper in .PDF format by clicking the download button below.

After optical power, polarization is perhaps the next most important test and measurement optical property of fiber optic components and systems. Specifically, with the introduction of coherent dual-polarization fiber optic communications, fiber optic sensing, integrated optics, and quantum communications and computing, polarization control has become an integral part of optical R&D labs and manufacturing lines.

In contrast to manual polarization controllers, multifunction polarization controllers (MPCs) employ electronic control of optical polarization actuators to convert any given state of polarization (SOP) to any other desired SOP. The waveplates within the MPC components can be made from various materials and technologies including magneto-optics birefringent crystals, liquid crystals, piezo-electric fiber squeezers or LiNbO3.

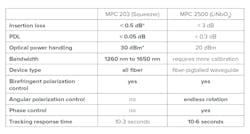

Two complimentary MPC technologies covering a wide range of applications are detailed below.

Fiber Squeezers: Advantages and Considerations

There are several technologies available to realize electronic polarization control. Among them, fiber squeezers mechanically compress the fiber creating birefringence. This “squeezing” of the fiber causes one polarization of light to be retarded with respect to its orthogonal polarization. Often, 3 or 4 voltage-controlled squeezers are sequentially placed at different orientations along the fiber to enable total control of the SOP, based upon the voltages applied (Figure 1).

Luna’s MPC 201, MPC 202, and MPC 203 combine fiber squeezer polarization controllers with proprietary polarization control algorithms to achieve a wide range of polarization control functions specifically scrambling the SOP and setting the SOP functions.

In addition to the squeezers’ seemingly simple method, this technology has other considerable advantages. Fiber squeezers are all-fiber devices and are as broadband as optical fiber, making squeezers available for any wavelength window. For instance, the most common squeezers, employing standard SMF fiber, operate across the standard datacom and telecom windows, 1,260 to 1,650 nm. Squeezers also have extremely low insertion loss, low back reflection, and low polarization-dependent loss (PDL). These characteristics make squeezer MPCs useful for high-precision PDL instrumentation.

Depending on the application, squeezers may not always be the best choice. The mechanical compression of the fiber causes the squeezer technology to have a response time in the µsec to msec range. Furthermore, the birefringence change is limited by the maximum pressure that can be applied to the fiber. As such, the SOP is not endlessly controllable. For applications where speed and endless polarization control are desired, Luna’s LiNbO3 polarization controllers are a better choice and complement the squeezer product line.

LiNbO3 Controller: Advantages and Considerations

In Luna’s LiNbO3 polarization control products, the optical LiNbO3 chip device has a defined waveguide to guide the light from the input fiber to the output fiber. A set of 3 electrodes straddling the waveguide form an electro-optic waveplate. Properly applying voltages to the electrodes will control a variable birefringence endlessly rotatable waveplate.

LiNbO3 controllers can have up to 8 waveplates, as shown in Figure 2, each with both birefringence and angular waveplate control, totaling 16 degrees of freedom. Not only does the LiNbO3 have a fast electro-optic response where the polarization can be modified in less than a microsecond, but the polarization control is endless. These underlying features allow for the implementation of flexible, ultra-fast, compound, and complicated polarization control functions.

The newly released MPC 2500 provides 7 different polarization functions.

Both of Luna’s polarization control technologies have functions to either control the SOP or mix up the SOP. MPC functions for stress and verification testing, include Luna’s “Scrambler,” “Spinner,” “Depolarizer” and “Randomizer,” each mixes up the SOP differently for specific testing purposes. These SOP functions serve both general lab uses and telecom system testing. Functions that set the SOP include “Tracker” or “Stabilizer,” “Acquirer” and “Paddle” modes drive the SOP to a desired state. These modes serve more specific applications like silicon photonics testing and coherent beam combination.

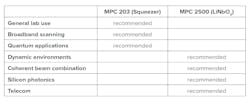

Table 1 includes all functional modes of operation of the MPC 2500 LiNbO3 .

The MPC 2500 is an updated and rebranded version of the NRT-2500, and joins the MPC 201, MPC 202, and MPC 203, squeezer-based test and measurement products, in a single multifunction polarization controller portfolio.

The LiNbO3 offers more functions than its fiber squeezer counterparts; however, a deeper consideration of the end-user's application requirements is crucial to properly select the optimal MPC product.

Fiber Squeezers and LiNbO3 Controller Applications: Two Complementary Technologies

Table 2 shows a more direct comparison between these technologies: one technology is strong when the other is less capable. Ultimately these tradeoffs will impact which one of these devices is best suited for the end-user’s application.

Quantum

Quantum communications applications, such as quantum key distribution, take advantage of the laws of quantum physics to protect data. In some implementations, the quantum channel uses a single photon in a superposition polarization state (qubit) to identify a hacker’s presence on the optical fiber or free space communication channel. Quantum computing employs quantum entangled qubits to enable calculations intractable by normal (i.e. classical) computers. MPCs are often used here to prepare the entangled qubits. In both quantum communications and computing, the optical quantum channel has only a few photons to carry the information. Hence loss in the fiber channel is intolerable. For these applications, the low-loss squeezer is the preferred MPC technology.

Coherent Beam Combination

Coherent beam combination is another relatively nascent field where amplified clones of a single laser are re-combined to create high-power directed energy laser sources for military applications, welding or cutting of metal parts. A number of techniques can be employed to scale up the power to a maximum level. These techniques generally favor the ultra-fast response of LiNbO3 controllers to combine a substantial number of beam elements.

The Tracker function on the MPC 2500 is optimized for these applications where the active tracking algorithm allows for a nearly perfect SOP and phase tracking, enabling the system to coherently align all beams to the master beam.

Silicon Photonics

As shared in Table 1, silicon photonics testing and telecom applications will require tests where polarization-dependent loss or polarization-dependent coupling needs to be evaluated. In these cases, users may desire to rapidly drive the SOP to maximize or minimize a feedback signal.

The ultra-fast LiNbO3 polarization control—driven by high slew rate voltage drive amplifiers—quickly responds to optical feedback and directs the change in SOP in milliseconds with the Acquirer function. The high precision and fast response of the MPC 2500 are preferable to increase the throughput of the optical wafer and die tests in a Si photonic chip fab.

Telecom

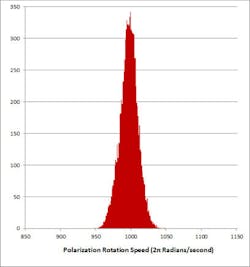

State-of-the-art, high-bit-rate communications systems, with coherent polarization-multiplexed modulations, must undergo receiver verification testing; this ensures the polarization demultiplexing capabilities are sufficient to track changes in the network SOP. The Spinner function of the MPC 2500 generates a well-defined speed of change for the SOP, rotating an electrooptic ½-waveplate up to 1 Mrad/sec (Figure 4). A second application function that exploits the high speed of the MPC 2500 is the Randomizer. It randomly jumps the SOP in 10 to 20 µs to emulate the ultrafast SOP changes caused by lightning along aerial fiber optic links.

Conclusion

MPCs can transform any arbitrary input SOP to any output SOP and create dynamic SOP functions to test, stress and evaluate optical devices. The versatility of these devices cannot be understated.

However, the different technologies used in MPCs can potentially lead to some confusion when it comes to deciding what type of MPC to employ. It may seem as though fiber squeezer MPCs are in direct competition with LiNbO3 technologies; this is not necessarily the case, as the advantages and considerations for each complement each other more than they conflict with each other.

Luna Innovations has leading experts in controlling the polarization and phase of light. The vast portfolio of polarization controllers can be credited to the established legacy and expertise of Luna’s two acquisitions: General Photonics (GP) and New Ridge Technologies (NRT). With Luna’s focus on fiber optic test and measurement, GP’s specialization in polarization control, and NRT’s legacy in both of these areas, the merging of these industry titans allows Luna Innovations to lead in polarization control, management, and measurement. Contact Luna Innovations today to learn more.