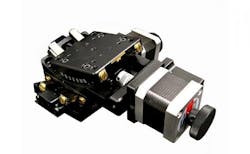

High Precision Stages

Goniometer stages can measure angles of objects such as crystals or move an object to a precise angular position along an arc, in relation to a fixed point in space. Optimal Engineering Systems (OES) offers stacked, precision aligned goniometer stages with a rotation center 50 mm above the upper stage. The lower (AK110-10) goniometer stage features a 65 mm x 65 mm table, ± 10-deg of rotation at a rate of 7-deg per second. The upper (AK110-15) goniometer stage features a 65 mm x 65 mm table, ± 15-deg of rotation at a rate of 10-deg per second.

Goniometers and stacked goniometers are used for identifying crystals, examining cutting edges of medical instruments, estimating hyperspectral bidirectional reflectance, gloss measurements, measurements of radiation patterns of LEDs, Directing lasers, aligning mirrors, and manufacturing of quartz oscillator plates using quartz cutting x-rays.

The precision, compact AK110-15-10 Goniometer stacked stage is available with a stepper, servo motors, optical encoders, or manual adjustment knobs. It has a footprint of just 169 mm x 169 mm and can be supplied plug-and-play with a motion controller. It is easily integrated into an inspection, testing, or manufacturing environment.

- repeatability: ± 4" (240 arcseconds)

- typical positional accuracy: ± 9" (540 arcseconds)

- typical backlash: ± 3" (180 arcseconds)

- The bench size is 65 X 65 mm and has a body weight of 0.75 kg

- It provides +/-15-deg of rotation at a maximum speed of 10-deg per second

- maximum load is 5 kg

- Range of Travel: +/-15-deg

- Gear Ratio: 1° (stage) : 252° (motor)

- Height of Rotation Stage: 55 mm+/-0.2 mm

- Travel Guide: Crossed-roller Guide

- Rotation Center Deflection Accuracy: 0.03 mm

- Maximum Speed: 10-deg/sec

Features

- made of aluminum alloy with an elegant black anodized surface

- calibrated indicator shows the angle of rotation

- drive mechanism is worm and worm gear

- worm gear ratio is 252:360.

- knob allows for manual adjustment

- knob may be replaced with an optical encoder for precision position verification

- stage is compatible with OES' line of Motion Controllers