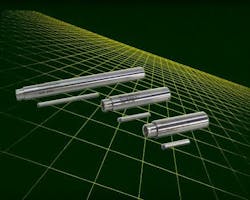

Rugged Hermetically Sealed DC-LVDT Position Sensors Operate In Corrosive Environments

Pennsauken, NJ, May 22, 2006 - Macro Sensors, a sensor company specializing in the manufacture of LVDT-based linear sensors and gaging probes, offers a family of rugged hermetically sealed sensors for general industrial use. Enclosed in a heavy wall, stainless steel housing, the HSE/HSER 750 Series of ¾” diameter DC-operated LVDTs are impervious to dirt, water, steam and other corrosive elements. Units are ideal for use in hydraulic cylinder positioning, valve position sensing, automatic assembly equipment and other industrial applications with hostile conditions.

In addition to its heavy-duty housing, the sensor’s coil windings are sealed against hostile environments to IEC standard IP-68. This allows for free movement of the core, while sealing out the surrounding media from the winding. The housing, bore liner and end washers are TIG welded, providing a hermetic sealing free from oxidation-producing faults that may cause leakage.

“LVDTs often must operate in environments where they are surrounded by corrosive or pressurized media,” explains Ed Herceg, N.A. Sales Manager, Macro Sensors. “By prohibiting media to enter the sensor windings, hermetic sealing protects the life and reliability of the LVDT in these conditions.”

A single-ended LVDT, the HSE Series 750 units terminate through a sealed axial connector that prohibits the core from passing completely through the coil assembly. Electrical termination for the HSER Series 750 DC-LVDTs, however, is made through a sealed radial connector located near one end. The radial connector offers a through-bore design that permits access to either ends of the LVDT’s core for better mechanical support and core guidance, and easier cleanout. The radial connector also offers a shorter installed length, compared to units of the same range with axial connectors.

Incorporating built-in electronics, both the HSE/HSER 750 Series 750 sensors provide the desirable features of an AC-LVDT, such as frictionless operation and dynamic response, with the added convenience and simplicity of DC input and pre-calibrated DC output. Units operate in conjunction with PLCs, digital indicators, A/D converters, computer-based data processors and QC data collection systems.

Available in ranges of 0.100 inch (2.5 mm) to 20.00 inches (500 mm), the HSE/HSER 750 Series LVDTs feature high resolution, excellent repeatability (repeatability error <±0.01% of FSO), and low hysteresis (hysteresis error <±0.01% of FSO). Standard maximum linearity error for any of these DC-operated sensors is ±0.25% of full scale output using a statistically best-fit straight line derived by the least squares method. A linearity error of less than or equal to ±0.10% of full-scale output is available as an option.

Operating from 24 V DC (nominal) or 15-24 V DC ±10%, 30 mA (nominal), the HSE/HSER Series 750 LVDTs offer a full-scale output 0 to 10 V DC. Operating temperature range is 0° to +160°F (-20°C to +70°C). Units are qualified at pressures up to 1000 psi (70 bars) and are suitable for numerous high-pressure applications.

Macro Sensors offers several standard options that permit a user to customize HSE/HSER Series 750 LVDTs, including Teflon® bore liners and metric threaded cores. In addition, Macro Sensors can provide mounting accessories, core extension rods, and DC power supplies. A mating connector plug is supplied with every unit.

About Macro Sensors

Macro Sensors’ extensive line of LVDT-based linear and rotary sensors are used for linear position measurement and feedback in a variety of industrial applications including factory automation, motion control systems, metal fabricating, automotive assembly as well as power plants, gas/steam turbines. Incorporated in 1994, the Company offers more than 200 years of cumulative design and manufacturing experience by its key staff in serving its OEM and end-user international customer base. On June 1, 2005, Macro Sensors was acquired by AST, manufacturer of state-of-the-art Micro-Electro- Mechanical- Structures (MEMS) based pressure sensors, transducers, and transmitters. Common applications of AST sensor products are in industrial OEM, hydraulic systems, fuel cells, medical gases, HVAC/R, refrigeration, oil & gas exploration/production, and off-road vehicles.HSE/HSER 750 General Specifications • Input Power 24 V DC (nominal) • 12-26 V DC, 25 mA (max.) • Full Scale Output 0 to 10 V DC, 5 mA (max.) • Output Noise & Ripple <5 mV rms • Frequency Response (-3dB) 250 Hz (nominal) • Linearity Error < ±0.25% of FSO • (< ±0.10% of FSO optional) • Repeatability Error < 0.01% of FSO • Hysteresis Error < 0.01% of FSO • Operating Temperature 0 °F to +160 °F • -20 °C to +70°C • Thermal Coefficient of Scale Factor -0.015%/°F (nominal) • -0.027%/°C (nominal) • Vibration Tolerance 20 g to 2 kHz • Shock Survival 100 g, 11 ms