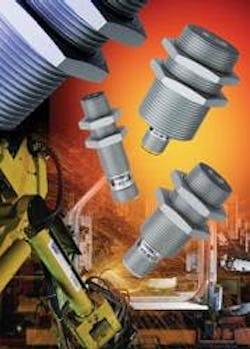

New Sensors Withstand Extreme Welding Environments

Contrinex has developed a new range of weld immune sensors that withstand weld spatter and resist electromagnetic field interference in induction welding and hardening plants. The zone immediately adjacent to a welding process is one of the most extreme environments for electronic components; and the intense levels of RFI created will cause the majority of inductive sensors to malfunction and, in some cases, change the output status. With these new sensors, the operating state does not change, even when embedded at the heart of these extreme environments. With tough copper-zinc alloy bodies, the sensors are sealed to IP67 and Teflon coated to withstand weld spatter and resist electromagnetic field interference and are supplied in M12, M18, M30 and 40mm x 40mm cubic (C44) formats. They are all PNP with a ‘normally open’ output and are fitted with a three-pin industry standard M12 connector. They are also CE approved with built-in output status LED and are short-circuit, voltage reversal and induction overload protected. These flush-mountable sensors have sensing distance from 3mm with the M12 up to 15mm with the C44. All these new Contrinex sensors have an identical operating distance on aluminum, brass and other non-ferrous metals as on steel. This means that when working with alloy components there is no shortening of sensing distance allowing sufficient clearance from the target to avoid front face damage, the most common form of sensor failure. This is an important feature as the welding of aluminum and other alloys is now becoming almost as common as steel.