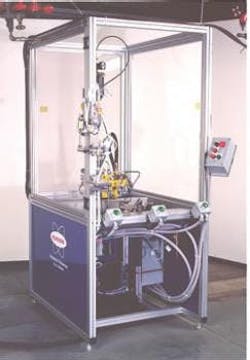

Single Station Braze Mate

The Braze Mate is the ideal automatic brazing machine for low volume applications or short runs of various part styles.

In production, an operator loads the part into a stainless steel fixture. A premeasured deposit of Fusion Paste Alloy is applied to the joint area with a hand-held applicator gun. As an option, this gun can be mounted to an automatic slide. The operator then activates dual, zero-pressure "touch" buttons, which initiates the machine cycle.

Automatically, a fixed pattern of gas/air burners advances into heating position. Oscillating flames eliminate "hot spots" at the assembly joint area. Once joining temperature is reached, the burner manifold retracts into idle position. A gradual air and water cooling sequence is followed by manual part inspection and final unloading. Depending on the application, 1 or 2 parts can be run each cycle.

Fusion offers three Braze Mate machine models:

- Braze Mate 100 (click here for specs.)

- Dimensions: 36" x 48"

- Single heat system; gas/air

- Typical Rate: 60 parts per hour maximum

- Braze Mate 150 (click here for specs.)

- Dimensions: 72" x 48"

- Single heat system; gas/air

- Typical Rate: 60-120 parts per hour maximum

- Recommended for large, multiple joint parts, or for running multiple

identical parts simultaneously.

- Braze Mate 200 (click here for specs.)

- Dimensions: 72" x 48"

- Dual heat systems; gas/air

- Typical Rate: 120 parts per hour maximum

Heat systems are independently controlled so

different parts can be joined simultaneously