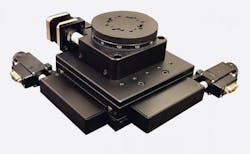

High-Resolution Alignment Stage

The XYR-03-01 Alignment Stage is a high resolution, high repeatability XY-Theta stage for applications such as: Angular glass cutting and grinding, wafer alignment, semiconductor handling, laser cutting and drilling. The linear resolution of the X and Y axis is 5µ (non-micro-step) or 0.125µ (20 micro-steps per step motor driver in use), the repeatability is 1.5µ, and positional accuracy is 5µ. The 1 mm per-turn lead screws and preloaded V-groove and crossed roller bearings add to the high precision and stiffness of the XYR-03-01 alignment stage. The linear travel of the X and Y axes is 50 x 50 mm.

The 100-mm diameter theta stage is driven by a precision 90:1 ratio worm gear. The resolution of the theta stage is 0.02O (non Micro-step) or 0.001O (20 Micro-steps per step motor driver in use). Repeatability is 0.005O, positional Accuracy is 0.01O and backlash is 0.005O.

Two-phase stepper motors are standard. The knob for manual adjustments of each axis can be replaced with an incremental encoder for position verification or closed loop operation. These black anodized Aluminum XY-Theta stages are easy to integrate into new or existing systems. Compatible Motion Controllers are available from OES and the XYR-03-01 Alignment Stage can also be ordered as a complete plug-and-play system.

Features:

- Compact

- Hollow or Solid Structure

- High Stiffness and High Precision

- Size From 100 X 100 mm

- Super-Thin and Light-Weight

- Pre-Pressurized the Special Cross-Roller Bearing

- Can Be Applied to the Optic Checking Devices for Continuity