Treating burn victims is usually a challenge given the severity of wounds, the delicate matter of skin, and the pain that results. Whenever I hear about burn victims, my mind always goes straight to the facial reconstruction stories and how far our medical technology has come over the years. It's amazing what can be done to help these victims.

Now researchers at the University of Waterloo have made new advancements in the treatment of burn victims.

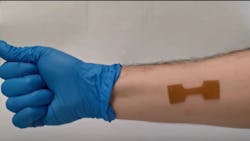

A new type of wound dressing that's 3D-printed using advanced polymers has been created to help speed up the healing process and bring pain relief to victims.

"To treat burn victims, we can customize the shape using a 3D printer, secondly, the material has fine-tuned surface adhesion, which is a key feature," said Dr. Boxin Zhao, a professor in Waterloo's Department of Chemical Engineering.

According to Dr. Zhao,—whose team has already been developing intelligent hydrogel materials for reusable wound dressings—the trick is to get the material to be able to easily adhere to the damaged skin while being just as easy to take off.

To create this material, the researchers used a 3D scanner to scan the patient's face and body parts to be able to customize it to their individual needs, helping the dressings to make good contact and adhesion with body parts such as the nose and fingers.

The advanced polymers the material is made out of includes a biopolymer derived from seaweed that has thermal properties and cellulose nanocrystals. The thermal property lets the dressing warm on the skin and then gently lowers to room temperature, slightly shrinking over the area, making it easier and less painful to remove. The material can also expand when put into a chilled environment, such as a fridge.

Not only does the dressing make application easier than standard bandages, but it also provides time-release medication for the patient, furthering pain relief over a longer period of time.

Since it's able to provide medication release, Dr. Zhao's team feels that the wound dressing can have applications beyond burn victims, including cancer treatment and the cosmetics industry. Specifically, he says that patients would no longer need to sit in a clinic during chemotherapy for hours as the dressing could provide the same constant release of drugs while they're at home, making them more comfortable. This dressing can provide a constant drug release outside the clinic setting, alleviating some of the challenges associated with traditional methods.

"We also envision applications in the beauty and cosmetic industry," said Zhao, Waterloo's Endowed Chair in Nanotechnology. "Cosmetologists can utilize 3D scanning technology to analyze their clients' facial features and customize hydrogel masks infused with specific facial and skin regimen products. Additionally, this innovative approach can benefit plastic surgeons."

A study highlighting the team's progress was recently published in the Journal of Colloids and Interfacial Science.

Dr. Zhao says the next step for the research group is to continue improving the material's properties to make it healthier and commercially viable.

Fun Innovations Friday | The Lighter Side of Manufacturing

Created by the editors of New Equipment Digest and Plant Services, Fun Innovations Friday/The Lighter Side of Manufacturing is a feel-good blog that showcases how advances in science, math, engineering, and technology are making our world more whimsical. Here’s another post that is guaranteed to brighten your day.

Fun Innovations Friday: Book a Stay at 3D-Printed Luxury Resort in Texas

Famous hotelier Liz Lambert has teamed up with ICON, an advanced construction technologies company, and BIG-Bjarke Ingels Group, an architecture firm, to create a 3D-printed paradise in Marfa, Texas.