Fun Innovations Friday: Cosmic Concrete to Build Homes on Mars

I never thought of concrete as needing a revamp as it's pretty stable in its uses. However, I'm also not well-versed in the world of concrete and I'll admit that I only recently realized that cement and concrete are not the same. In my defense, no one had corrected me before as I used the terms interchangeably.

Alas, there's a whole world out there invested in researching and developing new concrete formulations and uses.

Scientists from the University of Manchester in England have created what they call 'StarCrete', a new form of concrete that is twice as strong as traditional concrete that they say could be used to build homes on Mars. It's made from extra-terrestrial dust, potato starch, and just a pinch of salt.

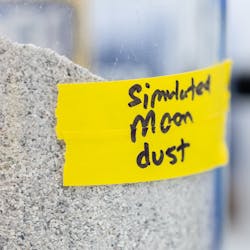

Currently, trying to build any type of infrastructure in space is so expensive it's almost impossible, not to mention its inherent difficulties. Infrastructure in space needs simple materials that are also easily available to astronauts. So, the scientists worked to create StarCrete. The scientists state that they simulated Martian soil mixed with potato starch and a pinch of salt to create a material that is twice as strong as ordinary concrete and is perfectly suited for construction work in extra-terrestrial environments.

The team published an article in the Open Engineering journal where they demonstrated how potato starch can act as a binder when mixed with simulated Mars dust to produce a concrete-like material. The test results showed that StarCrete had a compressive strength of 72 Megapascals (MPa). Ordinary concrete comes in at 32 MPa. They also tested out StarCrete made from moon dust, which was even stronger at over 91 MPa.

This same team originally tested out using human blood and urine as binding agents, but it didn't nearly have enough strength and also had the annoying need to routinely grab these bodily fluids from the astronauts. Not to mention trying to grab these bodily fluids in zero gravity.

“Since we will be producing starch as food for astronauts, it made sense to look at that as a binding agent rather than human blood. Also, current building technologies still need many years of development and require considerable energy and additional heavy processing equipment which all adds cost and complexity to a mission. StarCrete doesn’t need any of this and so it simplifies the mission and makes it cheaper and more feasible," Dr. Aled Roberts, Research Fellow at the Future Biomanufacturing Research Hub, The University of Manchester and lead researcher for this project.

He went on to say, “And anyway, astronauts probably don’t want to be living in houses made from scabs and urine!”

When testing if their method was feasible over the long term, they discovered that a sack (55 lb. [25 Kg]) of dehydrated potatoes contain enough starch to produce almost half a ton of StarCrete, which is equivalent to over 213 brick’s worth of material. A quick Google search says it could take anywhere from 7,000 to 8,000 bricks to build a 3-bedroom house.

An even greater proponent for this method is that a common salt, magnesium chloride—which significantly improves the strength of the material—can be obtained from astronauts' tears. It's also readily available on the surface of Mars, but that's no fun.

The team is now entering the next stages of this project which will include testing out StarCrete in actual application. Dr. Roberts and his team recently launched a start-up company, DeakinBio, to explore ways to improve StarCrete so that it can actually be used in a terrestrial setting.

They said that StarCrete could be used on Earth as a greener alternative to traditional concrete as it accounts for about 8% of our global CO2 emissions due to the process used to produce the material. Traditional concrete requires extremely high temperatures and high amounts of energy to be produced whereas StarCrete can be made in an "ordinary oven or microwave at normal baking temperatures", reducing energy costs for production.

The Lighter Side of Manufacturing

Created by the editors of New Equipment Digest and Plant Services, The Lighter Side of Manufacturing is a feel-good blog that showcases how advances in science, math, engineering, and technology are making our world more whimsical. Here’s another post that is guaranteed to brighten your day.

Looking for a Snack? Try a Rechargeable, Edible Battery

Researchers from Istituto Italiano di Tecnologia (IIT) have used products found in many pantries to develop a rechargeable, edible battery.

About the Author

Laura Davis

Editor-in-Chief, New Equipment Digest

Laura Davis is the editor in chief of New Equipment Digest (NED), a brand part of the Manufacturing Group at EndeavorB2B. NED covers all products, equipment, solutions, and technology related to the broad scope of manufacturing, from mops and buckets to robots and automation. Laura has been a manufacturing product writer for eight years, knowledgeable about the ins and outs of the industry, along with what readers are looking for when wanting to learn about the latest products on the market.