Editor's note: This article has been updated on March 21 to include Packsize's box machine, Seegrid's AMR enhancements, and Big Joe's AMR release from ProMat on March 20.

Packsize Collaborates With Walmart, Launches Ultra5 Box Machine

Packsize unveiled the Ultra5, a right-sized, on-demand box machine built around the recently announced X5 technology. The Ultra5 was built exclusively for Walmart and has already been installed in multiple fulfillment centers including the first of Walmart’s next-generation fulfillment centers.

The Ultra5 can produce up to 600 boxes per hour while contributing to less waste and fewer emissions by negating void fillers like plastic air pillows, reducing shipping emissions, and improving consumers' unboxing experience. By right-sizing boxes—ensuring no box is too large for the product(s)—the technology minimizes the costs and environmental impact of extraneous and unneeded corrugated boxes. It also improves parcel logistics, enabling retailers to fit up to 33% more boxes on freight and delivery carriers.

“By working with Packsize to develop the Ultra5 machine, we created an innovative packaging solution that tailors each box to the items we are shipping to customers, eliminating unnecessary waste and improving the unboxing experience once the package arrives,” said Prathibha Rajashekhar, senior vice president, innovation & automation, Walmart U.S.

Its industry-leading speeds contribute to faster throughput, with the ability to have orders packed, labeled, and ready to ship in as little as 30 minutes. The Ultra5 also includes what the company calls a “Flaps Down” feature, allowing boxes to flow through the packaging process by placing a paper band around the flaps to secure them to the sides of the box.

Seegrid Unveils AMR Interoperability

Seegrid Corp. has expanded the capabilities of its Palion AMRs: Palion Lift and Palion Tow Tractor now work in combination to load and unload carts with no human intervention.

Palion Lift uses 3D vision-based navigation with situational awareness to automate pallet movement, autonomously transporting up to 3,500 lb. and retrieving and placing goods at heights of up to 6 ft. The Palion Tow Tractor autonomously tugs cart trains and other payloads up to 10,000 lb., using autonomous navigation.

Palion Lift is now able to work directly with Palion Tow Tractor to load and unload carts to optimize and improve operations.

Big Joe’s New Autonomous Pallet Mover

Big Joe Forklifts’ first commercial AMR, the Pallet Mover, is very easy to program, use, and reprogram for different tasks, all from the user interface located on the machine. It helps to reduce the distance walked and time wasted by a person moving pallets from one location to another.

Developed in partnership with Thoro.ai, the Pallet Mover is an easy-to-deploy autonomous solution for floor-to-floor pallet transportation and drop-off that can be set up in less than one hour.

It does not require Wi-Fi to operate, handles a variety of workflows, and can map a warehouse in minutes and with simple training.

In addition, the AMR has obstacle avoidance and navigational logic to choose a path that is most efficient. Customers can create a zone of drop positions, enabling the Pallet Mover to pick a drop position based on its occupied or unoccupied status and set priority.

SnapControl by Synergy Logistics

Synergy Logistics, a developer of cloud-based WMS software, unveiled a centralized platform that connects and orchestrates all automation devices—including robots—within the warehouse.

SnapControl is a multi-agent platform within the SnapFulfil WMS that creates a device-agnostic, uniform approach to automation. The software prioritizes the work for you, automatically assigning tasks and workflows, evaluating which devices or equipment best match specific operations, and capturing data to assess the value of each device.

It connects to all types of devices, including but not limited to, RF, AMRs, conveyors, palletizers, putwalls, and AS/RS. Plus, it connects those devices in any possible transport method (API, CSV, etc.); if one type stops working, you can easily switch over to another device without stopping operations.

SnapControl uses bi-directional MQ Telemetry Transport (MQTT) messaging and decision-making between the WMS and the devices, automatically making the warehouse decisions for you.

Synergy says the software is ideal for mixed portfolios and multiple vendors, able to work with SnapFulfil's or other third-party WMSs, OMSs or e-commerce systems.

Essentially, SnapControl accelerates integration and gives you the freedom to choose the devices that best fit your tasks.

Agility Robotics Releases Next Generation of Digit, the Humanoid Logistics Robot

While Digit has been around for a few years, Agility Robotics unveiled the latest version today.

The new version includes advancements in payload, manipulation, perception, power, and Human-Robot Interaction (HRI) while maintaining a human-size form factor (5’9” and ~140 lb.). Newly designed end effectors—or hands—are optimized for grabbing and moving totes; reaching high or low, pulling, picking up, and placing objects. Additionally, Digit has a new head with LED animated eyes to allow for simple expressions to convey information and intent—improving human-robot interactions. For example, using straightforward body language and eye movement to indicate which direction it's about to turn.

Digit is designed to go where people go and do useful work safely in spaces designed for people, starting with bulk material handling within warehouses and distribution centers. It can navigate obstacles and walk on uneven surfaces in different environments, all while handling and moving objects—just like us.

Agility is opening up applications for a limited number of spots in the Agility Partner Program (APP) which will provide partners with an exclusive opportunity to shape the development of Digit’s skills and abilities, and will initially be the only way to purchase the latest generation Digit. Agility will work closely with APP partners to understand their warehouse workflows and pain points, and demonstrate how Digit can alleviate those issues.

For more information or to apply to join the APP, please visit https://agilityrobotics.com/partners.

Resonant Link's 400A Wireless Lift Truck Charger

The 19.2 kW, 400A wireless lift truck charger is the world’s fastest, safest, and most reliable wireless charger for lift trucks and material handling equipment, according to the company.

Suitable for autonomous and manual vehicles, it features a 10-in. air gap, ± 6 in. of misalignment, a foreign object detection system, and efficiencies of >90% throughout the parking range to ensure safe, speedy, and seamless charging.

Resonant Link’s 400A charger is battery agnostic, works with different vehicles, safe for harsh environments, and convenient.

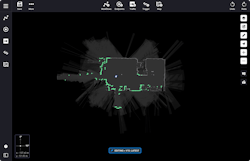

OTTO Motors Launches OTTO 600 and New Software

The OTTO 600 is OTTO Motors' answer for an AMR that offers strength and agility, able to move pallets, carts, and other payloads up to 600 kg (1,322 lb.). It has an all-metal construction and an IP54 rating.

Offering the capabilities of larger AMRs with the maneuverability to get around work cells, the 600 withstands dust and fluids; works quickly and safely alongside people; handles workflows including lineside delivery, work cell delivery, and palletizer to stretch-wrapper transport; and travels at speeds of 4.5 mph (2 m/s).

OTTO’s latest software release, 2.28, delivers faster and safer traffic movement and a new facility configuration interface for quicker workflow set-up.

In this software upgrade, OTTO has added new traffic management, easier facility configuration, interoperability, and new pallet types.

Raymond Launches New Lift Trucks

The Raymond Corp. launched a handful of new pallet trucks, carts, tow tractors, and more today.

- 8810 Side entry Pallet Truck: Model 8810 brings maneuverability to material handling and low-level order-picking applications. With a best-in-class turning radius, ergonomic features, and easy access from either side, the 8810 allows operators to work more easily and ride more comfortably.

- 8530 Rider Stacker: Ideal for horizontal transport, low-level order picking, and vertical pallet handling applications, the 8530 can handle floor or first-level loads with ease and can interface with racks and conveyors.

- 8630 Tow Tractor: Ideal for high-capacity, high-volume transport, and batch picking operations, the 8630 has 15,000 lb. of towing capacity and can work in tight areas. An 11% grade capability allows better performance on ramps.

- 4800 and 4810 Sit-Down Electric Counterbalanced Trucks: Models 4800 and 4810 are both for outdoor applications including lumberyards, building material suppliers, container yards, agricultural, and any others requiring an emissions-free lift truck.

We'll be back tomorrow with more product debuts from the show floor.