Robots are usually hard-headed—not just because their programming is a fixed option of subroutines, but also because they are almost always made out of metal and hard plastics. And for durability purposes, these robots need to have a hard exterior. It helps protect them from physical damage, environmental hazards, and helps provide strength for carrying large loads.

Nevertheless, engineers and researchers have increasly focused on developing soft skin robots to expand their use into other applications. Soft skins provide robots with the ability to handle shock loads, exhibit improved sensing, and even self-heal. In short, they create a better collaborative work environment with humans.

Shock-Absorbing Skin

The Massachusetts Institute of Technology has developed robotic skin that can absorb shock impacts, making it more durable. The Computer Science and Artificial Intelligence Laboratory have developed a 3D printed soft material that will allow robots to be more precise with their movements and provide improved durability. The team’s programmable viscoelastic material (PVM) technique allows users to program every single part of a 3D printed object to the desired levels of stiffness and elasticity needed for the task.

The PVM technique allowed researchers to 3D print a cube robot that moves by bouncing. The cube robot consists of the rigid body, two motors, a microcontroller, a battery, and inertial measurement unit sensors. Inside the robot, four layers of looped metal strip serve as the springs which propel the cube. The shock absorbing skin uses only 1/250 the amount of energy it transfers to ground to move.

This is possible through the use of viscoelastic material. The dampers found in viscoelastic are rubbers and plastics, which both have solid and liquid qualities too them. The viscoelastic material is cheap and compact, but only commercially available in specific sizes and damping levels. That is where the benefit of 3D printing comes in. By being able to tailor the material properties, the MIT research team could “program” the exact mixture of solid, liquid, and flexible rubber-like material called TangoBlack+. The PVMs could ultimately be used in other products such as running shoes, drones, headgear, sensors, and non-drone cameras to provide shock absorption.

Touch-Sensitive Robot

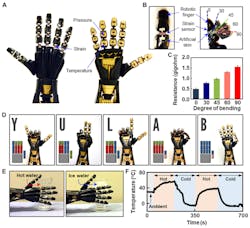

Human skin has the ability sense strain, pressure, and temperature. The research team at the University of Houston aimed to recreate the same capability in their newer robotic rubber skin. Rubber electronics and sensors are capable of normal operation even when they are stretched to 50% beyond their normal length. This would work as artificial skin on robots, providing them with flexible sensing capabilities. The rubber semiconductor starts out in liquid form and is poured into different molds, then scaled up to larger sizes or used as a rubber-based ink for 3D printing purposes.

The electronic skin is made by mixing tiny semiconducting nanofibrils—nanowires 1,000 times thinner than human hair—into a typical silicon-based organic polymer solution called polydimethylsiloxane. It is afterward dried at 140ºF; the solution becomes a hardened stretchable material embedded with millions of tiny nanowires carrying electric currents. The team applied the strips to the robotic hand, and the electronic skin worked as a sensor that produced different electrical signals.

By using the rubber electronic skin, a robot would be able to sense everything around it and provide a better collaborative work environment. The research team performed experiments whereby the electronic skin accurately sensed temperature of hot and cold water and translated computer signal sent to the robotic hand into finger gestures in the form of the American Sign Language alphabet.

Self-Healing Robots

While robots with softer skin offer a better sensing robot, they also are more vulnerable to cuts and tears when compared to a traditional plastic or metal exterior robot. The robotic research team at Vrije Universiteit Brussel has developed a rubber skin that can heal itself, mimicking the similar self-healing ability of human skin. The rubber developed is soft enough to provide sensitivity, yet strong enough to maintain its shape without inside support.

The rubber hand designed by the team, if cut, could be placed in an oven at 80ºC for 40 minutes, which induces the self-healing factor. The high temperature causes the wound to close. The polymer is made of a network of cross-links and the a Diels-Alder reaction occurs, creating new bonds across the damaged area. Once cooled, the new bonds firm, healing the material.

The designed soft gripper acts as an artificial muscle and has been tested on picking up various objects, as well as several variation cut tests. The healing factor behaved as expected, with the robot 98 to 99% functional after repairs. The process can be repeated as often as necessary without degrading the rubber. “Soft robots exist in several applications like grippers, crawling robots, [and] soft robot arms for endoscopy,” says study co-author Bram Vanderborgh. The material can be applied today to several applications, providing a safer and self-healing robot.