Rize, Inc., the maker of the Rize One 3D Printer, which was designed by some of the industry's top minds to slash post-processing time, has begun the next phase of its innovative approach to additive manufacturing with one more addition. Former Dassault Systèmes executive Andy Kalambi was named president and CEO last week to scale and further mature the flagship product.

"We're developing a product ready for prime time," says Kalambi, who adds since the beginning, Rize's measured development was intentional as not to "promise more than what's possible."

What's been possible so far has been decidedly impressive, earning the machine several awards, including an NED Innovation Award.

At the onset, the printer, made commercially available last June, enjoyed an embarrassment of rich features, providing solutions to all the aggravating baggage engineers must deal with during the 3D-printing process. The desktop printer (21.4 x 36 25.4 in. ) uses non-toxic materials, so it's safe to run in an office, and because the patented Rizium One is medically safe, it has garnered a lot of interest from the biomedical industry.

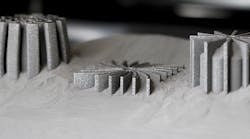

All industries would be pleased to know that "safe" doesn’t mean weak. By employing both FDM and Piezo Jetting in the patented Augmented Polymer Deposition (ADP) process, the build boasts extreme isotropic strength along the X, Y, and even Z axes. For prototyping or even end-use, Rize says parts printed on the Rize One offers mechanical properties that bring it closer to those manufactured via plastic injection molding.

Of course, the promise of nearly eliminating post-processing is what truly sets this printer apart. The machine jets a layer of Release One material between the supports and the part, creating a clear separation point. Instead of the laborious hassle of post-processing involving chemical baths, the engineer simply pulls the part off like it's a perfume sample in a magazine. The patented process can cut overall turnaround time by 50%.

Even with a seemingly disruptive tech, Rize has been slow to release too much too soon.

"What they did right was focus on getting the product robust and work with a few customers," Kalambi says. "My goal from here on is take action from an adoption perspective."

The former mechanical engineer has spent more than 25 years in leadership roles. First with SAP Asia, he helped proliferate ERP before anyone knew what it stood for, and more recently, as CEO of Enovia and 3DEXPERIENCE, he developing digital initiatives to improve the customer experience when using the 3D engineering software.

"Here I see a convergence of my life in this whole additive world, manufacturing supply chain and design innovation is all coming together in this additive space," Kalambi says. "I'll be able to truly leverage all the experience I've had over these years."

Part of that mission involves scaling out of the lab and lowering the cost of investment. The printer costs $30,000, a price mitigated by the saving in post-processing labor and other areas. Previously, Rize has said the printer can pay for itself in months.

The new CEO says part of the new strategy is to find a way to move the equipment away from big expensive 3D printing labs and putting them "as close as possible to the usage point."

Other goals are to bring in more materials, maximize productivity for the engineers, and produce industrial grade parts. Kalambi suggests that even metal 3D printing could use the ADP process.

Kalambi, who has worked in the Boston area for six years, after stints in Singapore, japan, and India, is confident the region, which has experienced a renaissance as an innovation hub, is the right place for this inflection point.

"For additive, it's become the center of the world right now," he says.

He also thinks Rize is the right company to be.

"In my career I have made long term bets," he says. "When I made my bet with SAP in '93, ERP was not even a word that was coined. I see that same potential in additive manufacturing. We're at the cusp of that starting."

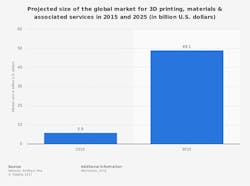

Globally, the software solution generated $32.6 billion in revenue last year, according to Statista. The site predicts 3D printing, valued at $5.9 billion in 2015, will increase to $49 billion by 2025.