To get where someone's coming from, you're supposed to walk a mile in their shoes. So by that rationale, to understand your workers' point-of-view, you should spend some time in their eyeballs. With Go Pros and smartglasses ubiquitously recording everyone's POV, you'll get the gist of their daily life, but you don't get to see what they're really focusing on in the picture.

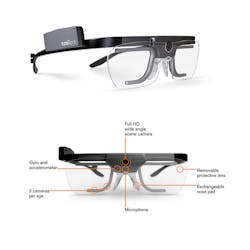

For that, you'll need wearable eye trackers, which look like smartglasses, but not only stream POV video to a researcher's tablet, but also precisely mark with a red dot where the lenses are honed in on, and presumably, the worker's attention.

Knowing that, Tobii Pro says, provides a window into the wearer's behavior. This is why the company recommends deploying their Tobii Pro Glasses 2— in conjunction with the Tobii Pro Insight team—to get a baseline of how your assembly line or plant workers view and engage their environment. From there, management can gather actionable intel, such as discovering any inefficiencies to improve performance or unsafe practices to avoid accidents.

"We live life visually and through eye tracking we can produce a reliable barometer of processes, training and cognitive load," says Tom Englund, president of Tobii Pro. "Our research consultants can apply the same eye tracking methodology to any business to ascertain the unique processes and skills needed for a more productive and safe work environment."

One clear way is comparing an experienced worker's eye-tracking data during an assembly to a novice's.

"This will help you discover what is behind the best practices of the more experienced people on your team. You can turn their individual skills into the company's knowledge so it can be transferred to new employees," Tobii explains on its website.

A recent study Tobii conducted at H&H Castings, a foundry in York, Penn., backed this up. With all that molten aluminum dripping down and fireballs bellowing up throughout the facility, it's not ideal for trainers to peer over a trainee's shoulder while they learn to pour metal. With the glasses, a supervisor can see in real-time exactly where the trainee's attention is directed.

For instance, watching the ladle's spout is critical to manage speed and avoid spills. If their gaze shifts, that's an obvious teachable moment, one that would happen before someone literally becomes a lead foot.

Staying still while pouring is also pretty important, and the wearable's gyroscope also senses movement, allowing the observer to know if a trainee is moving their head or body during the volatile process.

After the physical component of the study, which involved six workers filling, cleaning, transporting, and pouring, the video data was replayed so they can see where they need to improve.

"We hope the eye tracking video will save us two days per employee. Ideally, this would save us 400 hours of training time per year in that department," says Jacob Hammill, system manager of H&H Castings.

Here's a video of the study: