*Editor's Note: This article was originally published in August 2016. It has been updated and re-published with current information.

In 2016, Rize Inc., a 3D printing company that recently shut its doors in March 2022, came out with a new 3D printing process that leveraged patented new materials that essentially eliminated post-processing. While the company has shut down operations, it doesn't change that it brought a completely new 3D printing process to the industry.

It’s bad enough the industry has as many names as it does for the Internet of Things, (I vote for calling it Rapid Additive 3D Printing for Manufacturing Prototypes and call it a day) but now there are even more materials and 3D printing processes to research?

There’s ABS, ABS plus, Digital ABS, PLA, PPSF, ULTEM, SLA, Ceramics, Titanium, Kryptonite, Adamantium, and even chocolate. (Only two of these are fictitious). It’s an exciting time where there’s a printer and plastic for just about any design you can imagine, but this modern embarrassment of material riches can get a little overwhelming at times.

We want to help you build your knowledge base layer by layer, like a 3D Printer would so let’s start with some of the basics.

You’re probably aware that, along with materials, there are several different methods of 3D printing. There’s Fused Deposition Modeling, better known as FDM; Direct Metal Laser Sintering (DMLS); PolyJet; and Stereolithography, or SLA.

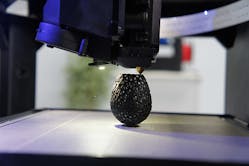

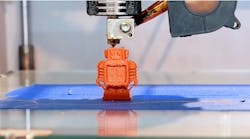

FDM works by extruding a melted thermoplastic filament via a head onto the build area in thin layers.

In a DMLS process, a bed of powdered metal is already in the build area, and a Ytterbium fiber laser micro-welds each layer.

Those two would be difficult to confuse, but SLA, developed by 3D Systems, and PolyJet, created by Objet, now part of Stratasys, are much more similar in approach and application. In our sister publication Industry Week, a Stratasys engineer, Andrew Graves explains the nuances of the related, yet distinct options:

"On the surface, it appears that stereolithography and PolyJet are identical twins. They both use UV energy to cure liquid photopolymer, after all. But a closer look reveals they’re more fraternal than identical.

Despite sharing a similar printing foundation, they use different print methods to achieve a fully cured product. The divergent build styles mean these methods are not always suitable for the same applications, making it important to understand the differences between the two processes. Chief among those are resolution and size, manufacturing speed, materials, and applications."

Here are some key features of each to help you decide which is best for your application:

PolyJet

How it Works

PolyJet works like an inkjet printer, squirting photopolymer droplets mixed with water-soluble support material, onto the build platform. While a 2D printer ejects its build area, a piece of paper, and starts again, the PolyJet cartridge is tailed by UV light to cure the layer.

Quality

The photopolymer is applied, again and again in 0.00063 to 0.00118-in. (0.02 to 0.03 mm) layers. Graves writes that “PolyJet prints in the finest layer resolution of any 3D print technology.”

Speed and Size

The finer resolution means the process could take a while, and this is the reason why Graves recommends 5 to 6 in.3 (82,000 to 98,000 mm3) as the ideal design size for PolyJet.

Materials

Because the jetted photopolymers can be jetted from different cartridges, a PolyJet model can comprise several different materials.

One model can have separate parts that are rigid and transparent, while others are flexible and opaque.

The Stratasys J750 3D Printer, launched in 2016 and replaced by the J850 printer in 2019, used six materials at once, drawing from a pallet of more than 360,000 colors.

The replacement, the J850 is capable of 3D printing at twice the speed and at a significantly lower cost, according the Stratasys. With the J850, users now have access to the full-color spectrum in their 3D printers (over 500,000 shades to be exact) and they can make use of color in combination with both clear and flexible materials.

In summary, materials used for PolyJet include digital materials, digital ABS plastic, rubber-like materials, high-temperature materials, transparent materials, rigid opaque materials, simulated polypropylene materials, and bio-compatible materials.

Stereolithography

How it Works

SLA was invented by the “Father of 3D Printing” Chuck Hull in the early 1980s and later co-founded 3D System. The company explains its process “utilizes a vat of liquid photopolymer resin cured by ultraviolet laser to solidify the pattern layer by layer to create or ‘print’ a solid 3D model.

Once the model is complete, the platform rises out of the vat and the excess resin is drained. The model is then removed from the platform, washed of excess resin, and then placed in a UV oven for a final curing.”

Check out the newest SLA printers on the market here.

Quality

The high is 0.002 to 0.004 in. (0.05 to 0.1 mm), and the standard is 0.005 to 0.006 in. (0.1 to 0.15 mm). 3D Systems says SLA “offers the most accurate type of fit/form prototype for the verification of any design before committing to your chosen production route.”

Speed and Size

Because SLA directs UV light to cure the parts via a rapidly moving mirror, it can end up building larger parts faster than PolyJet. The maximum size for either is 25 x 25 x 21 in. (635 x 635 x 533 mm). This could create a saving of up to 70% versus PolyJet, notes Graves, who manages Stratasys’ Stereolithography systems and operations.

Materials

SLA materials can mimic the properties of materials such as ABS, polycarbonate, and polypropylene, but cannot match the J850 in a range of materials or colors.

For larger functional prototypes, the process does excel, and can economically create investment casting patterns, which don’t require tooling as lost wax patterns do.

An intricate model might be good for a specific, custom model to be used by a heart surgeon, for example, but SLA would most likely be the better option for constructing a functional prototype.

Here’s Graves’ conclusion:

"Although they share many similarities, stereolithography and PolyJet should not be used interchangeably. When it comes to choosing between the two, a project’s application should be the deciding factor for any user. Force-fitting one process for all applications will likely leave your team with more hand labor—in other words, longer build times and higher costs. It could also mean a part that doesn’t meet the performance or aesthetic expectations."