Anouk Wipprecht is a Dutch FashionTech designer who creates designs that combine the latest in science and technology to make fashion an experience that transcends appearances. This year, she teamed up with Chromatic to envision what our future wardrobe can look like when 3D printing, textiles, and electronics are combined.

Originally debuted at Formnext in November 2023—the 3D printing trade show in Germany—, the motion-activated design is one of the first garments in the world to embed electronics within the 3D-printed elastomers.

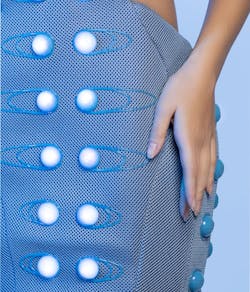

The avant-garde design used 3D printing to attach 75 flexible, 3D-printed LED domes to the fabric of the dress without adhesives or stitching, showing not just the potential of Chromatic’s 3D-printing technology for commercial use, but the potential of the 3D-printing industry as a whole.

Wipprecht's dress demonstrates the flexibility of Chromatic’s materials. Traditional 3D-printed materials tend to be brittle and hard, whereas Chromatic's ChromaFlow 70 offers a pliable, heat-resistant material that drapes and stretches more than four times its length without breaking or cracking. This flexibility allows a soft and seamless structural, functional, and aesthetic element that can be used for intimate and leisure apparel, sportswear, swimwear, and other apparel where silhouette and longevity are just as important as comfort.

ChromaFlow70 is a medium-strong, flexible polyurethane material with crosslinking, designed for oil-resistant applications at low to medium temperatures. In manufacturing, it's suited for seals and gaskets as well as vibration-damping applications in engine mounts. It offers smooth parts without post-processing, easy color matching, creating large parts without warping, and gas-tight printing.

"Using Chromatic’s 3D materials to print offers numerous possibilities for the fashion industry. For designers like me, who incorporate electronics into our creations, it provides a unique opportunity of embedding and securing electronic parts within the printing process,“ says Anouk Wipprecht. “This is my most wearable—and washable—3D-printed dress yet! As the electronics are enclosed, the material allows me to diffuse my LED lights, and the elastomer is both flexible and strong—making it excellent to bond to fabrics.”

Yes, you read that right. The dress is completely washable, though it's not clear if it's a wash-by-hand situation or if washing machines are fair game. I assume the former. But as Wipprecht stated, the electronic elements are completely enclosed into the structure of the dress as they are added in during the printing process.

While an LED dress doesn't seem to be aligned with manufacturing operations, it shows the capability of how this technology could be used in the future to create running apparel, bags, and footwear, along with products for automotive and aerospace interiors, outdoor recreational equipment, and personal protective equipment to increase safety innovatively.

“This collaboration is more than a partnership—it's a vision coming to life. By merging the genius of Anouk Wipprecht with our innovative 3D printing, we're setting the precedent for the future of fashion. We are embarking on a journey that amplifies the boundless integration of tech and art, opening doors for endless possibilities and applications in textiles and fashion,” said Cora Leibig, founder and CEO of Chromatic 3D Materials.

Fun Innovations Friday

Created by the editors of New Equipment Digest and Plant Services, Fun Innovations Friday is a feel-good blog that showcases how advances in science, math, engineering, and technology are making our world more whimsical. Here’s another post that is guaranteed to brighten your day.

Inventors of Transformers Toys Help Design Japanese Lunar Robot

The SORA-Q was jointly developed by Takara TOMY, a toy company; the Japan Aerospace Exploration Agency; Sony Group; and Doshisha University.