There are many theories as to how the Stradivari family got their violins and other string instruments to sound as pure and prodigious as they do, from how the family treated the wood to the 17th century "mini Ice Age" affecting the raw materials' density. There's no mystery behind how French engineer/musician Laurent Bernadac created his electric violin, the 3Dvarius, as enthralling to look at as it is to listen to.

It was 3D printing, of course.

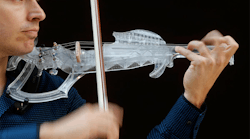

The 3Dvarius, a 3D-printed electric violin.

Photo: Thomas Tetu

The 3D printing process allowed the entire body to be created as one piece, and it was constructed on a computer, providing several musical advantages, according to 3Dvarius:

- Mass optimization keeps the structure light, freeing the musician’s movements.

- Acoustic study and wave propagation are optimized throughout the body of the instrument

- Mechanical resistance studies ensure proper resistance to the strings’ pressure

Bernadac, also a guitarist and drummer, digitally designed the 3Dvarius in 2012, and was holding a prototype under his chin a year later. On May 18, he is launching a Kickstarter campaign so his company can begin manufacturing them. After hearing this translucent fiddle, you may think Bernadac won it in a duel with the devil.

There's no info yet on how much one of these will cost, but it will definitely be cheaper than an actual Stradivarius, which can cost up to $20 million.