I’ll get into some more engineering detail about the role that adhesives play in engineering today, but first some fun. 3M built a scooter using nothing but its VHB tapes. This blog will talk about the design, build, and how not to get into trouble riding it around the office.

Bias warning: Yes, 3M sent me a kit, and yes, it was really cool and fun. However, even though it was a marketing ploy, I did feel that it portrayed a trend in the industry.

The Concept

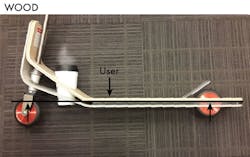

This scooter was designed with wood, plastic, and metal to show the versatility of tape with various materials. As I unboxed it, I was already impressed. The instructions were simple and well-written. I know this sounds dumb, but getting a product with poorly written instructions can lead to mistakes, frustration, and generally shows the company didn’t think about detail such as communicating with the customer. So, while 3M wasn’t trying to show off its attention to detail, this first impression gave me confidence that the build would go smoothly.

Next was what I feel should be on every product. If the line “use common sense” appears somewhere in the packaging, it should dismiss any frivolous lawsuit – of course, I’m also not a lawyer.

Fastener Trend

In the article “Trends in Adhesives: Replacing Mechanical Fasteners,” 3M’s Brent White wrote, “Adhesives, like mechanical fasteners, are easy to apply or install manually. And like mechanical screws and rivets, applying adhesives can also be automated. This is a growing trend as engineers across industry lines are always looking to lower production and labor costs and increase quality and consistency. Even the application of two-part adhesives can be automated using specially designed cartridges. These cartridges use dispensing applicators and static mix nozzles to ensure the adhesives are precisely and thoroughly mixed in exact ratios at the touch of a button.”

Stress Analysis

This is just one of the reasons why some manufactures are using adhesives and tapes to replace fasteners. Certain applications work well with adhesives, and they are demonstrated in the scooter build. The main part of the scooter—the deck—is supported by tape. Featuring a large surface area, the deck is load bearing and will experience a tensile force. If a design needs to have an adhesive on a structural component, tensile forces and a large surface area are ideal.

As the user steps on the deck, the rear axle that’s sandwiched between the layer of wood and metal will want to pull apart. The axle of the rear wheel will push up on the wood, creating a tensile force on the tape. Meanwhile, the metal part of the deck will see a distributed load from the axle pushing the wood up. In addition, a moment arm from the cantilevered beam is formed with the front wheel as the anchor.

While not debating if the forces are tensile or cleaving, this bond theoretically can handle about 3,200 lb. Though this sounds ludicrous, the weakest VHB tape I found had a tensile strength of 55 lbs./in2. An educated guess on dimensions puts the deck at about 4 × 23 in. with a hole that’s about 19.5 × 1.75 in., giving the tape about 58 in.2 of surface area to bond.

58 in.2 X 55 lb./in.2 = 3,190 lb.

The rest of the scooter’s design strategically reduced the load carried by the tape. The only major load-bearing point on this scooter is the front wheel. While a small strip of tape holds the upright rod to the front stem, it will mainly see downward forces. The tape does keep the two parts from sliding around, and might see minimal side or shearing forces. However, the most important job being done by this section of tape is reducing vibration.

Designing the joint to minimize peel or cleavage stresses on the bond line and maximize tensile, shear, or compressive stresses is desirable.

Note: The wheel and the upright rod that connects to the handlebar is all one piece, and the other piece is the stem that’s welded to the metal part of the deck.

Benefits

The adhesive distributes the load better than a fastener. A bolt or screw would only concentrate the load. In addition, the hole that was formed to make space for the fastener would create a stress concentration in the material.

Another benefit is that the materials used in this build have different coefficients of thermal expansion. Though perhaps not too important in this application, in a component exposed to varying temperatures or thermal cycles, the difference of this expansion could slowly weaken or even damage a fastened joint. Tape can provide a strong bond while distributing any force across a larger area. And, in the case of padded tapes, some flexibility can be designed into the joint to compensate for thermal expansion.

Furthermore, tapes are good for outdoor and hazardous environments. While traditional fasteners can be corrosive-resistant, adhesives are resistant and can seal an assembly to keep corrosives out.

In the article “Choosing and Using Structural Adhesives,” 3M’s Shari Loushin wrote, “There are several reasons why structural adhesives are chosen for a wide variety of assembly operations. Unlike mechanical fasteners, they don't damage substrates by needing drilled holes, and there's no heat distortion (a risk with welding). They can also join dissimilar materials without galvanic corrosion, work with different geometries, and don't concentrate stress at a few localized spots, thus increasing fatigue resistance. And after the joining processes, structural adhesives don't require refinishing steps or leave protrusions, so they are aesthetically more pleasing.”

One of the main drawbacks of adhesives and tapes is in applications that require maintenance. Taking tapes or adhesives apart is not favorable. While solutions are often made to break down the adhesive’s bond, traditional fasteners are better for applications that need to be taken apart, require regular maintenance, or need to open and close. Of course, once co-workers saw the assembled scooter, they said that I should take it back apart and shoot a video of me building it for our Facebook page.

Even though the office is clean, during shipping, the backing peeled on some of the tapes, allowing some of the cardboard dust to stick to one of the scooter’s pieces.

Another drawback is dirt. Everything worked out great when applying this tape in the office. However, if I were in a dirty area, or perhaps was trying to bond surfaces that are dirty, it would greatly impact the adhesive’s effectiveness. Keeping bonding areas clean can sometimes be difficult. Moreover, you have to hope that the technician will take the time to properly prepare the surface if an adhesive is used.

This build was fun and easy. While I think I could have done it with traditional fasteners, the build time and aesthetics would not be the same. Plus, I wouldn’t be able to make people nervous by telling them it’s only held together with tape. This was a great way to show the strength of 3M’s tape, and hopefully will change peoples’ perspectives of what adhesives can really do.

In the beginning of the article, I mentioned how to test ride this scooter around the office without getting in trouble. This was a simple task. I waited until everyone left for the day, and then rode it around the office. However, I did learn that you want to check to make sure everyone is gone, and that your boss isn’t working late… oops.

3M VHB Tape Details

- 3M VHB tapes are high-strength, double-sided acrylic foam tapes that quickly and easily create a long-lasting, durable, bond that can withstand vibration, moisture, and extreme temperatures, and builds strength over time.

- 3M VHB tapes can bond to a variety of materials, including aluminum, steel, glass, plastics, and painted and powder-coated surfaces, while maintaining a clean aesthetic and eliminating distracting, visible fasteners like screws and bolts.

- These multi-material bonding capabilities can also enable lightweighting in design.

- 3M VHB Tapes are efficient because they require less training than welding or riveting. Plus, 3M VHB Tapes bond on contact, eliminating drying, finishing, and cleanup time.

For more information, click here.