Over the last few years, as sensors climbed their way to ubiquity in industrial equipment, and electronics have grown ever smaller and more compact, M12 cables and connectors have become standard for most sensing systems.

The small size of the sets allows engineers to pass all of the information they need in a compact system that fits with the trend moving toward miniaturization that rules the field.

However, that trend doesn't apply to data and signal connections alone but power distribution as well.

Motion and automation control system, for example, are on the same course: They need smaller components, smaller assemblies, and low-profile designed that both optimize available space and maximize power distribution through the system.

Until recently, however, that power has been a bit of an issue.

These systems, no matter how small they get, still require a lot of power, and there has been no robust technology available to allow high-power connections in the smaller M12 size.

As a result, these systems designers have had no choice but to settle with bulky connectors capable of supplying the power they need.

Until now.

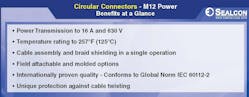

Harnessing a host of new technologies and materials developed by Hummel, the latest release from Sealcon—the M12 Power Circular Connector—finally brings high power capabilities to these electronic-makers and integrators need in the compact size they've always wanted.

The release, explains Raphael Brunner—VP of Operations at Sealcon—marks a major milestone in the age of miniaturization, and opens the door to an exciting new era of innovation in the electro-technology market.

We recently caught up with Brunner to discuss the M12 connector and what these new power capabilities can mean to the market.

NED: First off, can you give us an overview of the M12 and how it differs from other connectors on the market?

Brunner: This is all about miniaturization; it's about bringing more power, more amp and volt, in a smaller footprint.

This particular connector is the M12 size connector. It's a very common size in the market, widely used for many years in sensing technology & factory automation.

Sensing is usually low amp, low volt stuff. There are millions of cord sets out there and they do what they do.

But some people need to run power as well and there is nothing high power in that small format, in the rugged format, in the metallic format (field attachable) that is accepted by the market.

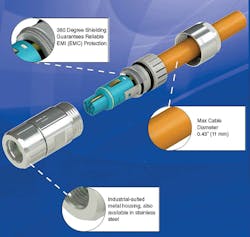

The M12 connector does that! Remember that most of the connectors used currently are made of plastic! We now offer the same but smaller and is produced in Nickel Plated Brass & Stainless Steel options for industrial use. With these materials, corrosion resistance and degradation are virtually eliminated as well as having the benefit of ease of installation.

NED: What kind of user would be interested in this kind of functionality?

Brunner: The motion control people, anybody who with small servos, drives, robots, conveyors and whatever else. Now they can pack a lot more power into small areas.

Motors, which used to have these large connectors on them, can now be

moved into corners of assemblies. Because the connector is so small and still has the power they need, new layout possibilities are available while also maximizing efficiency.

It offers the design engineers in motion control factory automation an avenue to pack in more power into smaller areas, which then frees up real estate for other things they want to add to a design.

It's basically like running fire hose pressure through a garden hose.

It can accommodate a larger cable than a normal M12 sensor solution, and that's why, with larger cable, you can have larger conductors, means more amps, more volts running through a small profile connector.

NED: How were you able to bring so much power down to this size?

Brunner: It's all about low profile, high power, sturdiness, ruggedness, high temperature. All of that was developed by Hummel, in alliance with an international connector solution house to meet tomorrow's standards.

In order to meet the high power in a small footprint, you had to address the heat dissipation issue, then, when overheating can become a fire and safety hazard.

So they created a flame retardant material, which has a high heat absorption ratio to accommodate the inevitable, because high power over small conductor can be very, very dangerous.

So they keep the safety factor in there and the whole thing is a grounded and shielded solution as well.

NED: You way this is part of the miniaturization trend in electronics. What does that trend mean to you and your business?

Brunner: The trend is toward miniaturization, whether we like it or not.

Tomorrow, everything will have to be smaller. Look at cell phones, look at everything we do.

Miniaturization is key to packing in more power into a smaller footprint.

That's the same in motion control, in factory automation, in robotics, everything the same deal.

Faster, more rugged, more power, more everything.

We are already there and soon everybody will have to follow suit. The M12 connector is the solution that so many people have been asking for and now it has arrived to fill the void. With the diverse industries and applications available, this product will save much frustration for designers and manufacturers alike.

There are already similar styles out there in plastic with larger profiles that don't reach exactly 16 Amps yet, so now is the time to try our newest M12 power connector. Our inside technical sales are happy to help spec in your perfect solution. We stand behind our products! They just haven't put the effort into developing these materials, but they will.