Engineers at Spirol International Corp., Danielson, Conn., are now applying an anti-corrosion process called thermal diffused zinc to the company’s fasteners. The process was invented and patented by a British metallurgist, Sherard Cowper-Coles, around 1900 when it was called Sheradizing and vapor or dry galvanizing. Over the years, improvements have been made to the zinc/iron diffusion process and it is now more widely known as ArmorGalv.

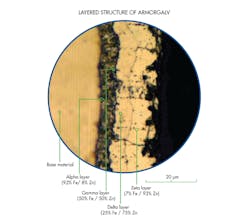

In the updated process, which is covered by ASTM A1059M-08(2013), parts to be coated are placed inside a sealed container and heated together with a mixture of powdered zinc to a temperature of 343˚C (650˚F). At this temperature the zinc mixture sublimates and fills the container as a vapor. Being soluble in iron, the vapor diffuses into all the surface of ferrous parts in the container. How much of the zinc mixture gets used is based on the total surface area of the part(s) in the container, which results in excellent control of the coating’s thickness and near total consumption of the zinc powder. Part size or the number of parts being coated is limited by the size of the container. After the diffusion, special topcoats and sealers are applied to complete the finish.

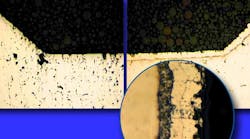

Before-and-after images show how a 100-micron (4-mil) coating of ArmorGalv fills in pores and the corrosion-resistant substance completely coats the powder-metal part.

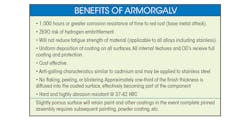

The finished coating is anodic to steel and as such, provides long-term sacrificial galvanic protection to the underlying metal. Compared to traditional electroplating, there is no risk of hydrogen embrittlement, adhesion is superior, coating thickness uniform, and all surfaces are covered. It is also affordable and durable. Another major plus: The U.S. Environmental Protection Agency says ArmorGalv approaches zero emissions and it has received recognition and awards for its contribution to pollution prevention. There is no hazardous chemistry and water consumption is extremely low.

Until now, this process had not been a commercially viable option for small components such as fasteners. Engineers at Spirol refined the process with small parts in mind, developed the necessary equipment, and worked to bring the coating to the fastener market at a reasonable cost. “ArmorGalv offers a low-risk, cost-effective, high-performance alternative to many of today’s platings and coatings,” says Spirol Applications Engineer Michael Pakso. “With ever-increasing performance and life-cycle requirements, this coating is an ideal solution for fasteners used in some of the most aggressive environments such as marine, automotive, mining, and industrial manufacturing.”