Much of subcontractor Driven Engineering's turnover comes from F1, although the cost cap imposed on teams over the past couple of years has reduced it somewhat, leading to a greater focus on aerospace, automotive, and general engineering work. Owner Ray Harris has historically machined mainly jigs, fixtures, and molds for F1 teams, which were telling him that to break into the supply of parts for race cars, he would have to improve his component inspection procedures and quality reports.

British coordinate measuring machine (CMM) manufacturer LK Metrology was a beneficiary of those conversations, as Mr. Harris placed an order for one of the company's AlteraC 10.7.7 CMMs.

During its build at the Castle Donington factory, the machine was reduced in height by about 4 in. (100 mm) so that it would fit through the entrance to Driven Engineering's latest factory unit in Havant and sit comfortably within a new quality room that was being added.

As part of the deal, a single license of PolyWorks Inspector software was supplied, which is swappable between the CMM and an articulated arm bought in 2020 when Mr. Harris worked in a previous location in Portsmouth.

"LK seems to be one of the metrology industry's best-kept secrets. I had not come across them before, but our local calibration company and inspection equipment supplier Mech Metrology & Power Tools introduced me. I got the impression that I would receive good support and backup, which so far has been the case. In addition, the CMM is well-built and the software provided is easy to use, including on the portable arm," said Ray Harris.

The step up to CMM metrology immediately brought in extra F1 work, mainly prismatic machining on three Hermle 5-axis, high-speed machining centers, two of which are fitted with automatic pallet storage and retrieval systems for automated, 24/7 operation.

Parts produced are typically for hydraulic manifolds as well as the race car's front and rear wings and floor. A lot of titanium is processed, plus stainless steel, aluminum, and some engineering plastics. Unlike jigs and fixtures, which have fairly open tolerances, the latest parts have drawing tolerances down to 25 µm (0.001 in.) true position, which is impossible to check using the portable arm. The CMM on the other hand is able to measure features an order of magnitude smaller, so is easily capable of completing the inspection tasks.

During programming in PolyWorks, Mr. Harris simply picks the features and profiles he wants to inspect. The software then automatically sequences the points for the most efficient inspection routine, including all axis movements, head rotations, and collision avoidance strategies. He describes the software as particularly easy to use and ideal for someone new to CNC CMM operation.

Data is captured both by touch-probing discrete points and tactile scanning using a Renishaw SP25M probe. Vastly more data is generated in a shorter time compared with touch-trigger probing only, enabling faster inspection and hence improved quality control. It also allows more comprehensive reports to be populated with richer information on the accuracy of freeform areas on components as well as dimensions. The PolyWorks software is able to present this data flexibly in a form that the customer prefers and is able to understand easily.

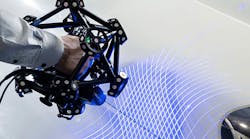

The pre-existing arm was supplied with a touch probe and a laser scanner but now is used exclusively with the latter sensor for speed of operation when inspecting, for example, one in five of a batch of 920 aluminum mold tool halves having a complex profile, machined for the aerospace industry. The CMM, on the other hand, was supplied with tactile probing capability only, although it was prepared for laser scanning with a view to adding that capability in the future.

Before he invested in the machine, Mr. Harris was invited to visit the Castle Donington factory to see a demonstration of an Altera 10.7.7 inspecting one of his components. It was fortuitous, as he was due to race at the Donington Park motorsport circuit nearby, having recently re-entered the sport by driving a GT car in the British Endurance Championship in early 2022. Unfortunately, the Donington fixture was canceled, so to save him the 350-mile round trip, he sent a water system for an F1 car together with the CAD model to the factory by courier and opted to view the demonstration online. LK showed two ways of inspecting the component, first by touch-probing to orientate it on the granite and then laser scanning, and secondly using an SP25M to probe and touch-scan the part.

Impressed with the latter metrology process, he decided to make the investment in the CMM and PolyWorks, whose ease of use is greatly helping his inspection productivity. Programming, due to the level of automation provided by the software, can be carried out in as little as 10 minutes, depending on component complexity, and, unlike when using an arm, can be done in advance from the CAD model.

Installation of the CMM has opened up a number of different avenues, as the availability of advanced metrology makes new business easier to win, especially tight-tolerance work. Additionally, Mr. Harris has now bought a Ginetta GT race car to hire out for events and intends to start manufacturing a proprietary range of parts for it, such as uprights, bearing supports, axle extensions, and drive shafts. The ability to control their quality on the LK CMM to a higher level than would previously have been possible will also enhance this new enterprise.