Allegheny Technologies Incorporated is forming a joint venture with GE Aviation to develop a new technology for manufacturing "meltless titanium alloy powder," meaning materials to be used in laser sintering or other additive manufacturing processes. The financial and other administrative aspects of their venture were not announced, but Allegheny Technologies (ATI) reported the venture would build a new pilot plant for producing the powder.

No schedule for the development was made available.

“We are pleased to join with GE Aviation to create this innovative next-generation technology joint venture,” stated Rich Harshman, ATI’s chairman, president and CEO. “The science of specialty metal powders is a transformative technology and we intend to maintain and enhance our industry-leading position.”

Additive manufacturing of metal parts (e.g., selective laser melting, or electron-beam melting), the powdered alloys are deposited in precisely defined patterns as layered sections of the final design. A laser or other heat source converts the powder to metal, bonding it to a preceding layer.

Titanium alloys of specific grades usually are atomized to achieve a reliable size and spherical structure to achieve the desired effect in the additive manufacturing process. In addition to AM processes, atomized spherical powders may be used in metal injection molding and hot isostatic pressing.

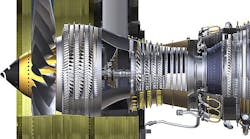

ATI manufactures titanium alloys, nickel-based alloys, and superalloys, along with stainless and specialty steels. It also produces finished products (including forgings), and lists aerospace and defense, “particularly jet engines”, as its primary customer group

ATI stated it would provide operational, technical, and project support to the joint venture, which will "leverage ATI’s technology, manufacturing, and quality leadership in the production of specialty metal powders and premium-quality titanium and nickel-based alloys".

As for GE Aviation, it will provide engineering and development resources and technical expertise on the use of alloyed titanium powders. GE Aviation designs and manufactures turbofan, turbojet, turboshaft, and turboprop engines for commercial and military aircraft. Its operation include several material development and additive manufacturing processes.

“Developing new materials is an important part of our vision for our business,” stated GE Aviation president and CEO David Joyce.