The Basics of Vibration and Damping in Engineered Designs

Download this article in PDF format.

Vibration is the periodic back and forth motion of the particles of an elastic body or medium. It usually arises when a physical system is displaced from its equilibrium condition and allowed to respond to the forces that tend to restore equilibrium.

The motion may be periodic, as in the motion of a struck pendulum. Or the motion can be completely random, such as the movement of a tire rolling along a rough road.

As defined in physics, vibration is the oscillating, reciprocating, or other periodic motion of a rigid or elastic body or medium forced from a position or state of equilibrium.

In some cases, vibrations can be advantageous—as with the reed in a woodwind musical instrument or in a vibratory parts hopper that dispenses discrete items from a funneled drum. But in many cases vibration is destructive. It can waste energy and create imbalances, friction, and failure in mechanical devices.

Vibration and sound studies are closely associated. Sound waves are generated by vibrating structures. These pressure waves also induce the vibration of structures or systems. Attempts to reduce unwanted noise are generally related to issues of vibration.

Types of Vibration

Free Vibrations

Free vibrations occur when a system is momentarily disturbed and free to move without restraint.

Consider a classic example such as when a weight is suspended from a spring. In equilibrium, the system has minimum energy and the weight is at rest. In contrast, if an external force pulls the weight down and releases it, the system will respond by vibrating vertically.

Consider another example of a child pulling back on a swing and letting go. The mechanical system vibrates at one or more of its natural frequencies and eventually damps down to motionlessness.

Forced Vibration

Forced vibration is when energy is added to a mechanical system—as in a system that is continuously driven by an external agency.

The periodic input can be a harmonic or a non-harmonic disturbance. A simple example is a child’s swing that is pushed on each downswing. Of special interest are systems undergoing simple harmonic motion and driven by sinusoidal forcing.

This causes the phenomenon of resonance. Resonance occurs when the driving frequency approaches the natural frequency of free vibrations. The result is a rapid take-up of energy by the vibrating system, with an attendant growth of the vibration amplitude.

Damped Vibration

Damped vibration is the depletion of energy. When a vibrating system is damped there is energy loss.

Depending on the motion inputs and the application’s modes of vibration, damping can be through dry-friction interfaces, mechanical devices, and arrangements that use viscous damping, and the integration of elastomeric engineered materials.

Viscoelastic materials damp vibration through a mechanism known as hysteretic damping. As these materials are distorted, internal friction causes energy loss.

Damping vibrations help manufacturers minimize equipment downtime and boost system efficiencies.

Vibration Damping for Machinery

Vibration damping can happen through proper implementation of viscoelastic components. When vibrations are damped, they are removed from the system in a couple of ways. They can be absorbed into materials that release vibration energy as small amounts of heat energy, or they can be changed to different frequencies that don’t resonate with the parts of the machine.

Viscoelastic materials are often used for vibration damping. Here are a few of the most common uses.

Unconstrained Damping

A pad of viscoelastic material is created for moving parts of the machine. The pad sits between the parts that are causing excess vibrations.

As the parts move, it conforms to the movement to absorb some of the vibration energy. It then stores that energy and releases it as heat energy. This removes vibration from the system and keeps the machine from breaking down or making too much noise. Unconstrained damping is by far the simplest way to address vibration in machinery.

Click here to download the Sorbothane Engineering Design Guide.

Constrained Damping

In this type of vibration damping, the viscoelastic damping material is lined with a thin piece of flexible metal. It works similarly to unconstrained damping, but it can be more efficient.

Constrained damping in this may be used for machines that need close control of vibrations.

Tuned Viscoelastic Damping

Directed damping, designed to keep specific wavelengths of vibrations out of a system. This is often because of the need to keep resonant frequencies from causing serious damage to machinery or motors.

The Difference Between a Vibration Isolator and a Vibration Damper

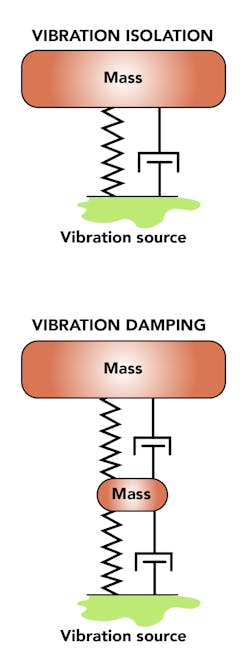

Damping vibration is the dissipation of energy. Isolating vibration is the prevention of vibration transmission.

Vibration Isolator

A good vibration isolator lowers the natural frequency of a system to below the excitation (or disturbing) frequency. Keeping these two frequencies “out of sync” greatly reduces the problems of vibration.

As some in the industry define it, common isolators separate the vibration source by flexible slabs that in a definition of the system in dynamic physics act as damper, spring, and mass.

Many isolators exhibit some inherent damping, though the latter can degrade their isolation ability by magnifying transmitted vibrational forces.

Vibration Damper

In contrast, a good vibration damper takes mechanical energy out of the system. Properly designed metal springs and rubber mounts can be good isolators but have almost no damping capability.

As some in the industry define it, common vibration absorbers separate the vibration source by damping as well as a second mass attached to the system through other dampers.

Oil dampers (dashpots) have good damping capability but no isolation capability.

Foam products can be good isolators but have limited life.

The Main Characteristics of a Vibration Damper

- Good damping coefficient

- Wide temperature range stability

- Long fatigue life

Sorbothane — A One-of-A-kind Vibration Solution

Sorbothane is a polyether-based polyurethane.

It is formulated for enhanced viscoelastic properties. Sorbothane is consistently effective over a wide temperature range (-29 to + 71°C). Because Sorbothane is a non-Newtonian material, stress is not proportional to strain.

Instead, mechanical energy is “lost” by conversion to heat.

The response of Sorbothane to a load is highly dependent on the rate of force application (frequency-dependent responses).

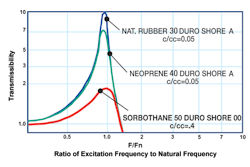

Sorbothane is highly damped which makes it particularly desirable for difficult applications that require operation near or at resonant frequencies.

Sorbothane is available as custom-molded parts, select standard shapes, and in sheet stock in a variety of thicknesses and sizes. Parts can be specified in durometers ranging from 30 to 80 on the Shore 00 scale.

The most effective static deflection for Sorbothane with a shape factor between 0.3 and 1.0 is in the range of 10 to 20%.

Viscoelastic material pads such as these custom Sorbothane components can isolate vibrations. The manufacturer designs and produces them in a variety of shapes, sizes, and durometers. Each part is specific to the design and function requirements of the end product and client parameters.

Controlling Vibration

Low transmissibility (amplification) at resonance demonstrates the damping superiority of Sorbothane over other elastomers. Low transmissibility means less damage to sensitive components. Isolation at large frequency ratios also shows a capacity to isolate vibration.

For more information on vibration solutions and Sorbothane capabilities, call (800) 838-3906 or visit sorbothane.com.